OUTLINE:

A Complete Guide to Blow Off Valves

171

171If you're looking to boost your car's turbo performance, understanding blow-off valves (BOV) is key. These small yet powerful components play a big role in improving efficiency and enhancing your driving experience.

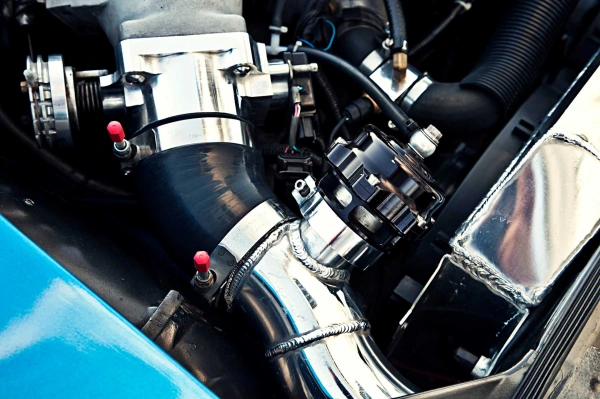

Image Source: Full Race

In this ultimate guide, we'll explore the different types of blow-off valves— from atmospheric to recirculating—and help you understand how each type affects your vehicle’s performance, sound, and reliability. Whether you're tuning your car or just curious about how they work, this guide has you covered.

What Is A Blow off Valve and Its Function

A Blow-Off Valve (BOV) is a crucial component in turbocharged and supercharged engine systems, designed to protect the engine and turbocharger while improving overall performance. It is typically located on the intake system and works by releasing excess pressure that builds up when the throttle is suddenly closed, such as during gear shifts or deceleration.

Function of a Blow-Off Valve

-

Pressure Relief:

When the throttle closes quickly, the airflow to the turbo is suddenly cut off, causing a pressure buildup in the intake system. The BOV releases this excess pressure to prevent damage to the turbocharger and other components. -

Prevent Compressor Surge:

Without a BOV, the pressure can cause compressor surge, a phenomenon that can damage the turbo over time. By venting the excess pressure, the BOV helps prevent this surge, improving the longevity of the turbo and the entire engine. -

Improved Engine Response:

By releasing the pressure, the BOV allows the turbo to continue spinning at a consistent speed. This helps the engine respond more quickly when the throttle is opened again, reducing turbo lag and improving overall performance. -

Enhanced Sound:

Blow-off valves often produce a distinctive "whoosh" or "pfft" sound when they release pressure. This sound is a signature of turbocharged vehicles and is a popular feature among car enthusiasts.

The Working Principle of A Blow off Valve

Image Source: Turbosmart

Blow off valve, its role is to release excess pressure in the intake system of a turbocharged or supercharged engine, to ensure that the engine runs smoothly, and to protect the engine parts. Here's a step-by-step look at how it works:

Boost pressure accumulation

As soon as you step on the gas, the turbocharger compresses the air and sends it into the engine intake. This creates a boost pressure, which is particularly important for engine performance. However, if the throttle suddenly loosens (such as when shifting or slowing down), the compressed air has nowhere to go.

Stress-induced surge

If we don't let off the boost pressure, we'll have a surge in the intake system. The surge can cause turbulence, causing compressors to surge, damaging turbochargers and making engines run inefficiently.

Bleed valve activated

As soon as the throttle is loosened, the air flow suddenly decreases, causing a vacuum, and the bleed valve is activated. The valve is spring-loaded and opens when it senses a change in pressure, releasing excess boost pressure, which is usually either vented to the atmosphere or recycled back into the intake system.

Release pressure

When the valve opens, the compressed air is discharged. If it is an atmospheric vent valve, this air is discharged to the outside, making a unique "whew" sound. If the recirculating vent valve is used, the air is returned to the intake system in front of the turbocharger, maintaining system pressure and avoiding unnecessary emissions.

The valve closes and the system returns to normal

After the excess pressure is released, the valve automatically closes and the engine returns to normal operation. The turbocharger can continue to spin, keeping the speed steady and reducing turbo lag, so that the driver can accelerate again, the throttle response is faster. And a sense of elegance.

Various Types of Blow off Valve

Blow-off valves (BOV) come in different types, each designed for specific performance characteristics and applications. The two primary categories are Atmospheric and Recirculating, but within these categories, there are further variations based on design, functionality, and sound output. Here’s a breakdown of the most common types of blow-off valves:

1. Atmospheric Blow-Off Valve (Vented to Atmosphere)

-

Function: The atmospheric BOV vents the excess boost pressure directly into the atmosphere.

-

Sound: It produces a loud, distinctive "whoosh" or "pfft" sound when releasing pressure, which is popular among performance enthusiasts for its aggressive sound.

-

Performance: While it effectively reduces turbo lag and prevents compressor surge, it may not be street-legal in all regions due to the emissions it releases.

-

Use: Often used in motorsport and performance builds where sound and performance are prioritized over emissions compliance.

2. Recirculating Blow-Off Valve (Plumbed Back to Intake)

-

Function: The recirculating BOV releases excess pressure, but instead of venting it to the atmosphere, it routes the air back into the intake system, usually before the turbo.

-

Sound: This type tends to be quieter than the atmospheric BOV because the air is returned to the intake and not released into the open air.

-

Performance: It helps prevent the loss of air and reduces turbo lag while keeping the air in the intake system for better efficiency and smoother operation.

-

Use: Ideal for street vehicles where emissions and noise control are a concern, as it keeps the system closed-loop.

3. Dual-Port Blow-Off Valve

-

Function: This BOV combines both atmospheric and recirculating functions. It has two ports, allowing it to vent some air to the atmosphere while returning some back into the intake system.

-

Sound: It produces a blend of the loud whoosh of the atmospheric BOV and the quieter recirculating sound.

-

Performance: Offers the benefits of both types: noise enhancement and reduced turbo lag. It is more versatile in handling different driving conditions.

-

Use: Often used in performance cars that seek a balance between sound and efficiency.

4. Sequential Blow-Off Valve

-

Function: A sequential BOV uses multiple stages or valves to release boost pressure. The valves open at different times depending on the level of pressure in the intake system.

-

Sound: Typically produces a series of sounds as each valve opens, creating a more dynamic effect than a single-valve BOV.

-

Performance: Offers smoother pressure relief and is often used in highly modified or multi-turbocharged setups to manage larger volumes of boost pressure.

-

Use: Common in high-performance and racing setups, where precise control over boost pressure is necessary.

5. Pneumatic Blow-Off Valve

-

Function: The pneumatic BOV uses a spring-loaded diaphragm and vacuum signal from the intake system to open and close the valve.

-

Sound: Typically quieter than atmospheric BOVs but still effective in releasing pressure.

-

Performance: The diaphragm is sensitive to changes in boost pressure, making it responsive and reliable for standard turbo setups.

-

Use: Common in stock or mildly modified turbocharged vehicles, offering a balance between noise control and effective pressure management.

6. Electronic Blow-Off Valve

-

Function: An electronic BOV is controlled by an electric solenoid rather than a traditional spring and diaphragm. The solenoid opens and closes the valve based on electronic signals.

-

Sound: Can be tuned to produce varying levels of sound based on driver preference or setup.

-

Performance: Provides precise control over when and how boost pressure is released, making it suitable for advanced tuning and performance setups.

-

Use: Typically used in high-tech or heavily modified turbocharged cars, where electronic control can be integrated into the engine management system.

7. Hybrid Blow-Off Valve

-

Function: A hybrid BOV is a combination of two or more types of valves or uses both mechanical and electronic control for enhanced performance and adaptability.

-

Sound: Varies depending on configuration, but generally offers flexibility in sound and pressure relief.

-

Performance: Optimized for specific use cases, offering maximum performance while maintaining control over airflow and noise.

-

Use: Suitable for heavily modified cars or custom builds, where the owner requires a tailored BOV solution.

How to Choose the Right Blow off Valve for particular purpose

-

For Street Use & Emissions Compliance:

Choose a recirculating BOV. It keeps air within the intake system and minimizes noise while ensuring emissions compliance. -

For Performance & Sound:

If you want an aggressive sound and don’t mind venting to the atmosphere, an atmospheric BOV is ideal. It releases air directly to the environment, creating a loud whoosh. -

For a Balanced Solution:

Opt for a dual-port BOV. It combines both atmospheric and recirculating functions, giving you performance benefits and moderate sound. -

For High-Performance or Multi-Turbo Systems:

Go for a sequential BOV for precise control over boost pressure in multi-turbo setups, or an electronic BOV for advanced tuning and control. -

For Stock or Mildly Modified Vehicles:

A pneumatic BOV is a reliable, straightforward choice that balances performance and ease of use.

FAQs: Does A Blow off Valve Increase Horsepower

Image Source: Motor Trend

A blow-off valve (BOV) does not directly increase horsepower. Its primary role is to release excess boost pressure when the throttle closes, preventing compressor surge and protecting the turbocharger. By maintaining turbo efficiency and reducing lag, the BOV can enhance throttle response and ensure smoother power delivery. While these improvements can optimize overall performance, they do not generate additional engine power on their own. Instead, the BOV works as a supportive component to maintain the health and efficiency of the turbo system, which indirectly helps sustain consistent performance.

Final Verdict

Understanding the different types of blow-off valves is essential for optimizing your turbocharged engine’s performance. Whether you prioritize sound, efficiency, or emissions compliance, there’s a BOV suited to your needs. Choose wisely to enhance your driving experience, protect your turbo, and ensure smooth, reliable performance.

Disclaimer: The views and opinions expressed by individual authors or forum participants on this website do not represent the views and opinions of Chipsmall, nor do they represent Chipsmall's official policy.

share this blog to: