OUTLINE:

How to Choose Bulkhead Electrical Connector: An In-Depth Tutorial

416

416These versatile and reliable bulkhead electrical connectors are designed to bridge the gap between different electrical systems, ensuring efficient and secure transmission of power and signals. Whether you're working on industrial machinery, automotive applications, or aerospace projects, the right bulkhead electrical connector can make all the difference.

What Is a Bulkhead Electrical Connector

A bulkhead electrical connector is a type of connector designed for use in applications where electrical connections need to be made between two separate enclosures or panels. It consists of a male and female connector pair, each mounted on a separate enclosure, with the bulkhead wiring connector acting as a barrier or wall between them.

These connectors are typically used in applications where it is necessary to connect electrical components or systems across different sections or compartments, while maintaining the integrity and protection of the enclosures.

What Are the Different Types of Bulkhead Connectors

These different types of electrical bulkhead connectors serve specific purposes and can be selected based on the requirements of your application.

From appearance:

- Circular Connectors: These connectors have a round shape and are used to transfer power, signals, or data between devices in various industries. Circular connectors offer excellent resistance to environmental factors like moisture and dust, making them ideal for outdoor or industrial applications.

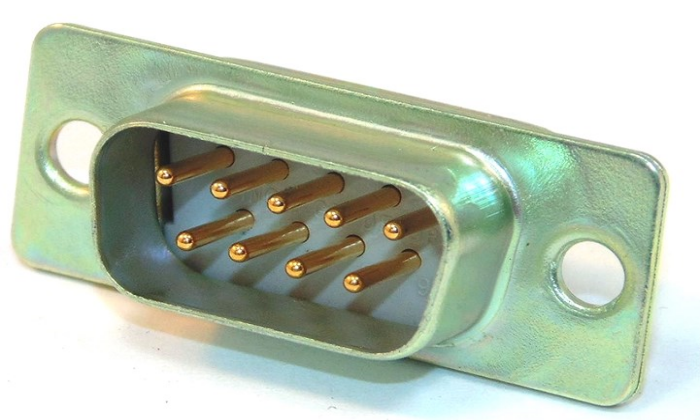

- D-Sub Connectors: D-Sub connectors have a distinct "D" shape and are commonly used for connecting computer and industrial equipment, allowing communication and data transfer. They are known for their durability and reliability, often used in scenarios requiring multiple pin connections.

- Rectangular Connectors: These connectors have a rectangular shape and are used for electrical connections, providing versatility for linking multiple wires or circuits. Rectangular connectors can accommodate a high number of connections within a compact space, making them suitable for complex electronic assemblies.

From function:

- USB Connectors: USB connectors are used for connecting devices like computers, smartphones, and other electronics, allowing data transfer and power delivery. They come in various forms, such as USB Type-A, Type-B, and Type-C, each designed to cater to different devices and requirements.

- Coaxial Connectors: Coaxial connectors are used for connecting RF (radio frequency) or video signals, commonly found in telecommunications, cable TV, and satellite systems. These connectors provide excellent shielding and signal integrity, crucial for high-frequency applications.

- Power Connectors: Power connectors are designed to handle high-power applications, allowing the transfer of electrical power between devices or systems. They are built to handle high current and voltage levels, ensuring a safe and reliable power connection.

Benefits of Bulkhead Coaxial Connectors

- Greater flexibility:

Bulkhead coaxial connectors can pass through circuit boards, barriers or panels, making them extremely versatile. This flexibility is invaluable when designing and installing communications systems, enabling efficient connections in a variety of environments. Their adaptability ensures that they meet the needs of applications ranging from industrial settings to complex network systems. -

Safe and robust connections:

Bulkhead coaxial connectors feature a threaded barrel design that ensures a secure and stable connection. This design prevents accidental disconnection due to vibration or movement, which is critical in applications where signal integrity is paramount. The robust connection is ideal for use in demanding conditions where reliability is essential. -

EMI Shielding:

The metal housing of bulkhead coaxial connectors provides excellent electromagnetic interference (EMI) shielding. This feature minimizes the effects of external interference on signal quality, ensuring reliable communications even in noisy environments. Effective EMI shielding is critical for applications requiring stable, clear signal transmission. -

Easy to install and maintain:

Designed for straightforward installation and maintenance, bulkhead coaxial connectors are easily mounted on panels or housings. This easy installation facilitates quick connections or replacements without major disassembly. Their user-friendly design makes them ideal for applications where downtime needs to be minimized.Bulkhead coaxial connectors offer significant benefits including greater flexibility, secure connections, excellent EMI shielding, and ease of installation and maintenance, making them a reliable choice for a variety of critical applications.

Factors to Consider When Choosing a Bulkhead Electrical Connector

When choosing a bulkhead electrical connector, you can take these factors into consideration:

- Environmental circumstances: Make that the connector is built to endure the unique circumstances of your application, such as temperature, moisture, dust, and vibration.

- Connector Type: Determine the number of pins/contacts and signal type necessary.

- Durability and Reliability: Choose connections made of high-quality materials that can withstand frequent usage without degradation.

- Connector Compatibility: Check that the connector's pin layout and wire gauge match those of your cables or wires.

- Industry Standards and Certifications: Look for connectors that meet quality and safety requirements.

- Cost and Supplier: Determine the cost and select a reputed provider who provides dependable items and excellent customer service.

How to Choose The Right Voltage Bulkhead Electrical Connector

- Determine the voltage requirements: Identify the voltage level that the connector needs to handle. This can be found in the specifications of the electrical system or equipment you are working with.

- Check voltage rating: Ensure that the bulkhead electrical connector has a voltage rating that matches or exceeds the voltage requirements. The voltage rating should be clearly stated in the connector's specifications.

- Consider safety standards: Verify if there are any specific safety standards or regulations applicable to your application. Ensure that the chosen connector complies with these standards to ensure safe operation.

- Verify insulation properties: Insulation is crucial for electrical connectors to prevent voltage leaks and ensure proper electrical isolation. Choose a bulkhead connector with adequate insulation properties suitable for the voltage level you are working with.

Common Applications for Bulkhead Electrical Connectors

Bulkhead electrical connectors are vital in several industries due to their robust and reliable performance. In aerospace and defense, they ensure stable connections in aircraft and military equipment under extreme conditions. The automotive industry uses them for connecting electronic systems within vehicles, offering durability against vibrations and temperature changes. In marine applications, these connectors provide waterproof and corrosion-resistant connections essential for ships and submarines. Industrial machinery relies on bulkhead connectors for secure power and signal connections in factory automation and robotics. Their versatility and durability make them crucial for ensuring efficient operations across various sectors.

Frequently Asked Questions (FAQ)

When choosing a bulkhead electrical connector, you can take these factors into consideration:

- What materials are used in bulkhead electrical connectors?

Typically, stainless steel, aluminum and high grade plastics are used for the shell and copper or brass for the contacts to balance strength, durability and conductivity. - How do I ensure a secure connection?

Carefully strip the wire insulation, insert the wire fully into the terminal, tighten the terminal screws securely, test with a multimeter, and check periodically for looseness or corrosion. - Can bulkhead electrical connectors withstand high voltage?

Yes, please select connectors that meet or exceed the voltage and current requirements. - How do I maintain bulkhead electrical connectors in harsh environments?

Use connectors with appropriate environmental ratings (e.g. IP67, IP68), inspect seals regularly, and apply protective coatings or covers. - What are some common applications for bulkhead electrical connectors?

They are used in industrial machinery, automotive systems, aerospace, marine equipment, and telecommunications to provide reliable connections in environments that require secure sealed connections.

Conclusion

Electrical bulkhead connectors are important for making secure electrical connections between separate enclosures or panels. They come in different types and are used in various industries. Anyway, When choosing a connector, you should consider a variety of factors such as compatibility, durability and voltage rating.

Disclaimer: The views and opinions expressed by individual authors or forum participants on this website do not represent the views and opinions of Chipsmall, nor do they represent Chipsmall's official policy.

share this blog to: