OUTLINE:

Uncovering how A Bypass Valve Work

393

393Hey!Are you also curious why those fluid things flow so smoothly without any problems? Do they have any tricks that can prevent pressure from rising and make everything flow so smoothly?

Image Source:PSGDOVER.com

Hey, the answer lies in those low-key bypass valves, they are like heroes behind the scenes, silently taking care of everything.

Let's talk about these bypass valves this time, what they look like, how they work, and why they are so important on different devices.

Let's take a look at these mysterious little things together and see how they help keep your device in the best condition!

Basic Knowledge of Bypass Valve [Concept&Function]

The bypass valve plays a crucial role in fluid control systems, acting like a traffic police officer responsible for ensuring smooth fluid flow while also keeping an eye on pressure levels.

Once the pressure is too high, like exceeding the set warning line, the bypass valve will immediately open another channel, allowing the fluid to take a different path.

In this way, the system will not collapse or malfunction due to excessive pressure.

Its working principle is super simple: when the pressure in front of the valve is too high, it will automatically open, allowing the fluid to bypass. It's like installing a safety net on the system to protect it from harm.

So, what exactly can it do?

Control pressure: It is like a pressure regulator, ensuring that the pressure is not too high, so as not to damage the system.

Manage flow: In addition to controlling pressure, it can also make the fluid flow more smoothly in the system, especially when different flow rates are required, it can make the system perform better.

Improving efficiency: By maintaining stable pressure and smooth fluid flow, bypass valves can also make the entire system more efficient. In this way, not only can energy be saved, but the various components of the system can also be made more durable.

In short, bypass valves are very useful in various industries, such as air conditioning, heating systems, hydraulic systems, water treatment plants, and so on. They are all key roles in ensuring the stable operation of these systems.

Illustration of How A Bypass Valve Work[In Detail]

Image Source: Butterfly Valve.com

Firstly, a few "buddies" of the bypass valve:

Valve body: It's like the headquarters of a bypass valve, hiding all the small parts needed for work inside.

Executor: This guy is a little expert in opening and closing valves. He can be manually turned or automatically sensed, and can move as needed by the system.

Import and export: It refers to the import and export of fluids, where fluids enter and exit, in a simple and clear manner.

Bypass path: This is a backup path. In case the main path gets blocked, the fluid can take this detour.

Spring helper: Place a handle on the actuator to make it more stable when opening and closing the valve.

Now let's talk about how it works:

Regular work:

Normally, the actuator will make the bypass valve obediently allow the fluid to pass through the main path, such as through the heat exchanger or filter, so that the system can operate smoothly.

Urgent 'firefighting':

However, if the pressure in the system is too high, too hot, or the water flow is too fast, the actuator will quickly take action to open the bypass valve. It's like the 'alarm' in the system sounding, either automatically or manually, depending on how the system is set.

Diversion method:

As soon as the bypass valve is opened, the fluid no longer takes the main path and instead takes the bypass path. In this way, the pressure, temperature, or flow on the main road will decrease, protecting vulnerable components such as water pumps or filters.

Restore to its original state:

When the system stabilizes, the actuator will close the bypass valve again, and the fluid will return to the main path, and the system will return to normal.

See, the bypass valve is such a clever "little firefighter" who always appears when the system needs it to protect its safety.

Where should a bypass Valve Be Installed

Installing a bypass valve depends on the situation and which system it serves. Let's talk about several common installation locations:

Heating and air conditioning system: For this type of system, it is best to install a bypass valve near the pump or heat exchanger. In this way, once the pressure is too high or the temperature is too high, it can promptly divert the water flow and protect the system from harm.

Water heating system: In this system, the bypass valve needs to be installed on the return pipe. In this way, it can control the water flow, maintain the balance of the system, and keep the home just right warm.

Water filtration system: When installing this system, remember to place the bypass valve in front of the filter.

Car cooling system: When installing a cooling system on a car, the bypass valve should be placed near the radiator. Its task is to manage the flow of coolant, protect the engine from overheating, and make the car run more smoothly.

Industrial equipment: In industrial equipment that requires pressure control, bypass valves are also essential. It needs to be placed in a location that requires decompression to prevent damage to the equipment due to excessive pressure.

Anyway, installing a bypass valve depends on the situation and finding the right place. This is the only way to maximize its effectiveness and protect our systems and equipment.

How Does A Bypass Valve Regulate Pressure and Flow in Fluid Systems

The bypass valve is a master in fluid systems, as it regulates pressure and flow through several key techniques:

Pressure sensing and action

Pressure monitoring: The system is equipped with sensors that constantly monitor the pressure value. Once the pressure exceeds the set upper limit, it will send a signal to the bypass valve to open.

Executive control: This actuator can be manual or automatic. It adjusts the degree of valve opening and closing according to pressure changes, allowing the system to flexibly respond to various situations.

Diversion method

Normal work: Normally, the fluid obediently goes through the main path, such as passing through a heater, cooler, or filter.

Bypass start: However, if the system feels that the pressure is too high or the flow rate is too fast, the bypass valve will open to find a small path for the fluid to pass through. In this way, the pressure and flow on the main road will decrease.

Pressure regulation

Maintain Balance: The bypass valve helps maintain pressure balance in the system by diverting flow, preventing delicate components from being damaged due to excessive pressure.

Feedback loop: As the pressure on the main road decreases, the bypass valve will slowly close (if it is designed this way) to ensure that the flow is only diverted when needed.

flow control

Adjustable flow rate: The bypass valve can also adjust the flow rate! It controls the amount of diversion to ensure that the flow meets the system's requirements. When demand decreases or pressure returns to normal, the valve will partially or completely close, allowing the fluid to return to the main path.

Improve efficiency: In this way, the system can operate more efficiently because it can prevent pumps and other equipment from overloading.

protection system

Prevent damage: The bypass valve is like a bodyguard, protecting pumps, filters, and other important components by diverting and regulating pressure. In this way, the system will not experience headaches such as cavitation, overheating, or mechanical failures.

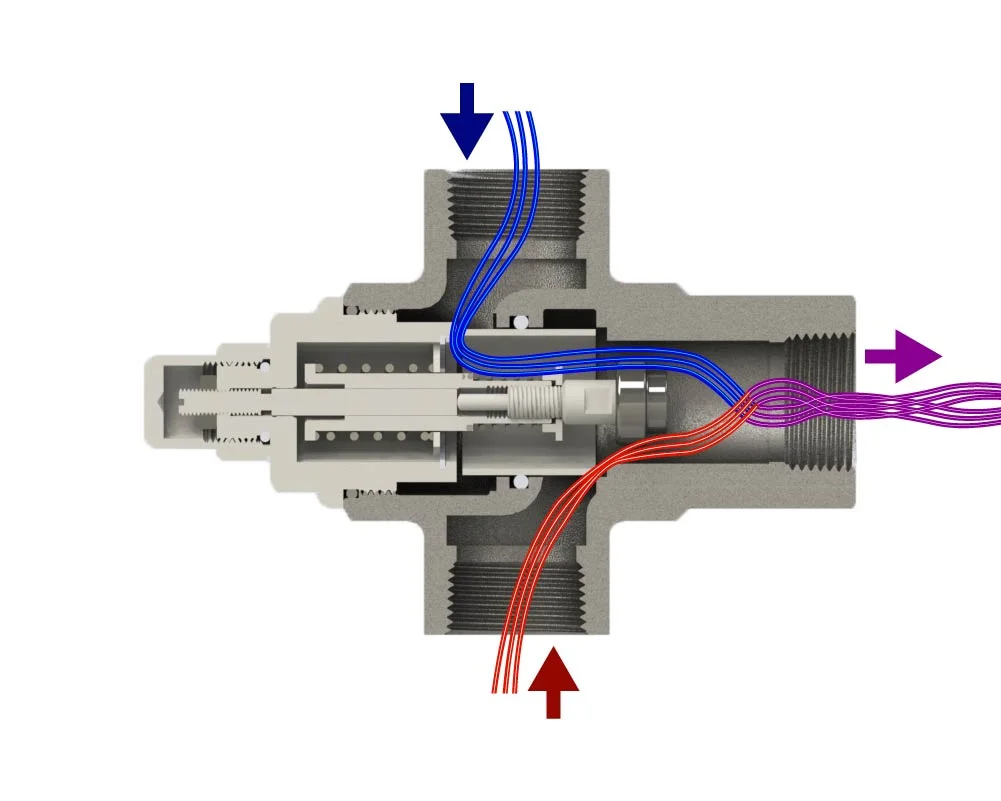

What Happens Inside A Bypass Valve when System Pressure Exceeds the Set Limit

Image Source: Thermostatic Valves

When system pressure exceeds the set limit, a bypass valve activates to protect the system and maintain optimal operation. Here’s a detailed breakdown of what happens inside a bypass valve in such a scenario:

1. Pressure Sensing

Monitoring: The bypass valve is equipped with a pressure sensing mechanism, often integrated with the actuator. This mechanism continuously monitors the pressure within the system.

Threshold Exceedance: When the pressure exceeds a predetermined limit, the sensing mechanism triggers a response.

2. Actuator Response

Signal to Open: The increase in pressure sends a signal to the actuator. This can be a mechanical response (like a spring mechanism) or an electronic signal (in automated systems).

Opening the Valve: The actuator adjusts the valve position, typically by moving it from a closed position to an open or partially open position.

3. Fluid Redirection

Bypass Channel Activation: With the valve open, fluid begins to flow through the bypass channel instead of the primary circuit. This secondary pathway allows fluid to circumvent the area experiencing excessive pressure.

Pressure Relief: By diverting some of the flow, the valve reduces the pressure in the primary circuit. This helps protect sensitive components such as pumps, filters, or heat exchangers from damage.

4. Flow Management

Adjustable Flow Rates: Depending on the design, the bypass valve may allow for variable flow rates. It can fully open to relieve high pressure or partially open to fine-tune the pressure within acceptable limits.

Balancing System Pressure: As fluid is diverted through the bypass channel, pressure in the primary circuit decreases, helping to restore balance in the system.

5. Restoration to Normal Operation

Pressure Stabilization: Once the pressure falls back within the acceptable range, the actuator will gradually close the bypass valve, allowing fluid to return to the primary circuit.

Feedback Mechanism: The system continuously monitors pressure, ensuring that the valve remains in the correct position to maintain optimal performance.

The End

Simply put, knowing how the bypass valve works is particularly important for maintaining efficient and durable fluid systems in various applications. The bypass valve is like a master regulator of the system, which can intelligently adjust the flow rate according to pressure changes, protect vulnerable components, and make the system run more smoothly. Whether it is in the heating and air conditioning of the home, car cooling, or water filtration, bypass valves play a crucial role. They can balance the pressure of the system, making it safer and more energy-efficient, and are an indispensable part of modern technology. With our increasing understanding of fluid control technology, the importance of bypass valves is becoming more and more apparent. They are the major contributors to supporting the stable operation of important systems.

Disclaimer: The views and opinions expressed by individual authors or forum participants on this website do not represent the views and opinions of Chipsmall, nor do they represent Chipsmall's official policy.

share this blog to: