OUTLINE:

Ultimate Guide of Bulk Capacitor: The Mystery of Energy Storage

501

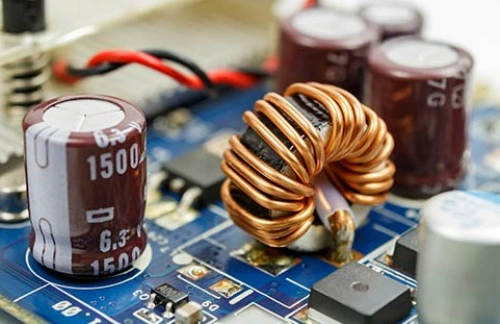

501Bulk capacitor, generally referred to as a capacitor with a capacity ranging from micrometer to farad. In this section, a comprehensive introduction of bulk capacitors will be shown for your reference.

Types of Bulk Capacitors

According to the different materials and structures, they are mainly divided into aluminum electrolytic capacitors, tantalum capacitors, ceramic capacitors and thin film capacitors.

|

Types of Bulk Capacitors |

|

|

Electrolytic Capacitors |

Electrolytic capacitors are polarized capacitors that use an electrolyte to achieve high capacitance values, commonly used in electronic circuits for filtering, energy storage, and smoothing in power supplies. |

|

Ceramic capacitor (MLCC) |

Chip multilayer ceramic capacitor (MLCC) is a kind of miniaturized, high-capacity, high-performance passive electronic component, which is widely used in various consumer electronics, communication equipment, computers and automotive electronic products. |

|

Thin film capacitance |

A thin film capacitor is a capacitor formed by wrapping two plastic films with metal electrodes into a cylindrical shape. |

|

Super capacitor |

A Super capacitor, also known as an electrochemical capacitor or double-layer capacitor, is an energy storage device between a traditional electrolytic capacitor and a battery. |

Electrolytic Capacitors

Features

- Large capacity range: The rated capacity can be very large, suitable for occasions where a large amount of charge storage is required.

- Cost-effective: Because the materials and production equipment used are ordinary industrial materials and equipment, the production cost of electrolytic capacitors is relatively low.

- Polarity: Electrolytic capacitors usually have a positive and negative electrode, both of which can not be reversed, otherwise the capacitor may be damaged.

Advantages

- Suitable for power supply circuits: In power supply circuits or intermediate frequency and low frequency circuits, electrolytic capacitors are often used for power supply filtering, decoupling, signal coupling and time constant setting.

- High power density: In power electronics applications, the power density of electrolytic capacitors is higher than that of double-layer capacitors.

Drawbacks

- Limited service life: Electrolytic capacitors usually have a shorter life than other types of capacitors due to the evaporation of the electrolyte.

- Poor temperature durability: At lower temperatures, the ESR (equivalent series resistance) and impedance characteristics of electrolytic capacitors are restricted and performing-poor.

- Sensitive to mechanical stress: Electrolytic capacitors are more sensitive to mechanical stress, which may affect their performance and reliability.

Where to buy quality electrolytic capacitors>> Best Capacitor Brands: Top 20 Electrolytic Capacitor Manufacturers in 2024

Ceramic Capacitor (MLCC)

Features

- Portable characteristic: MLCC owns multi-layer structure, which makes it suitable for high-density installation.

- Non-polarity: ceramic capacitor is easy to use, being able for AC circuits use.

Advantages

- High reliability: ceramic capacitors can remain stable in various environments, regardless of pressure resistance and seismic performance.

- Low loss: Low medium loss provides MLCC with good signal transmission effects.

Drawbacks

- Capacity varies with temperature: The capacitance value may decrease as the temperature increases.

- Susceptible to voltage and current: Excessive voltage or current may lead to internal short circuit or breakdown.

- High dielectric loss: Low efficiency compared with traditional capacitors.

- Complex production process: The manufacturing cost is high, and the process requires multiple processes and sintering processes.

Here is the >> List of Ceramic Analog Suppliers

Thin Film Capacitors

Features

- High voltage class: Thin film capacitors can be designed to withstand higher operating voltages than other types of capacitors.

- Small volume and weight: Due to the structure of thin film capacitors, they can provide large capacitance values in a small volume, suitable for space-constrained applications.

Advantages

- High tolerance: Thin film capacitors can achieve small minimum tolerances and high tolerance accuracy, which is very important for precision circuit design.

- Good self-resonant frequency: The self-resonant frequency of the film capacitor is high, which is suitable for applications where fast charge and discharge are required.

Disadvantages

- Higher cost: Film capacitors may be more expensive to produce than some other types of capacitors.

- Possible environmental sensitivity: Some film capacitors may be sensitive to humidity and other environmental factors, which may affect their performance and reliability.

Super Capacitor

Features

- No special charging circuit: The charge and discharge circuit of the super capacitor is relatively simple and does not require a complex charge management system.

- Environment-friendly: Super capacitor does not contain harmful substances such as heavy metals, and can be recycled, in line with environmental protection requirements.

- Overcharge and over-discharge do not affect service life: Compared with batteries, super capacitors do not have a negative impact on their life when overcharged or over-discharged.

Advantages

- High energy density and high power density: Capable of delivering a large amount of energy in a short period of time, suitable for applications requiring instantaneous high current output.

- Low internal resistance: Compared with aluminum electrolytic capacitors, the internal resistance of super capacitors is larger, but it is still suitable for some specific application scenarios.

- Easy to detect: The remaining power can be read directly, which is convenient for energy management and control.

Disadvantages

- Voltage limit: The operating voltage is usually low, limiting its use in high-voltage applications.

- Unstable capacitance: The capacitance may be affected by various factors such as temperature, voltage and service life, and there is a certain volatility.

- Electrolyte leakage risk: If used improperly, it may cause electrolyte leakage and pollution to the environment.

Factors to Consider When Choosing a Bulk Capacitor

When choosing bulk capacitors, you need to consider several key factors:

1. Type of capacitor

If you can find the correct capacitance value, go with the film capacitors as opposed to any other type. Especially electrolytics, which are the worst in reliability. However, you may not sometimes have a choice since film capacitors cannot be manufactured with large capacitance values. But when you can, it is a wise choice to use a film capacitor.

2. Capacity and pressure resistance

Capacity and voltage resistance are the most important parameters in capacitor selection, because they are directly related to whether the design can achieve the desired function.

3. Frequency characteristics

The performance of capacitors at different frequencies is also important, especially in high frequency applications, where it is necessary to choose a capacitor that can provide good performance in the desired frequency range.

4. Practical application

Depending on the actual application, different types of capacitors may be required. For example, in cases where a large number of parallel connections are required to increase the total capacity, ceramic capacitors and thin film capacitors may be better choices.

When selecting bulk capacitors, you need to consider the above factors and make a proper selection based on the specific requirements.

Bulk Capacitor Alternatives

When looking for alternatives to bulk capacitors, there are several options to consider. While film capacitors are reliable, they are relatively expensive and have low capacitance density, which can lead to physical size issues that limit their use in some applications.

So with buck converters, the main things you want to keep in mind for capacitors are capacitance, voltage, rating, ESR, and ripple current rating. Additionally, it's common to have some large capacitors with a moderately high ESR and also some lower capacitance ceramic capacitors due to their lower ESR. If you're worried about the output ripple, it is useful to simulate the whole circuit in the circuit simulator of your choice.

Besides, as an alternative to multi-layer ceramic capacitors (MLCC), solid polymer capacitors are a viable option in many applications. Their key features compared to MLCC can be considered according to specific application requirements.

Then, for small capacity aluminum electrolytic capacitors, you can consider using epoxy encapsulated tantalum capacitors, especially in the case of extreme temperature cycles.

Fourthly, active capacitance reduction circuit, a newer alternative that reduces the required capacitance value by transferring the pulse power component to a small energy storage element using a two-way DC-DC converter is also helpful. This approach can not only improve reliability, but also achieve physical size and cost reduction in applications above a certain level.

When choosing an alternative, the specific requirements of the application need to be considered, including factors such as operating voltage, temperature range, size limitations, cost and reliability.

Bulk Capacitor FAQs

1. How to size a bulk capacitor?

The higher the capacitance, the lower the deviation. Therefore, the size of the input bulk capacitor is determined by the size of the output current transient and the allowable input voltage deviation. The amplitude of the input voltage deviation during a transient is directly proportional to the load current change.

2. What is a capacitor calculator?

This is the capacitor energy calculator, a simple tool that helps you evaluate the amount of energy stored in a capacitor. You can also find how much charge has accumulated in the plates. Read on to learn what kind of energy is stored in a capacitor and what is the equation of capacitor energy.

3. How do you read a capacitor size?

The first two digits will indicate the base capacitor value in picoFarads. The third digit will indicate a multiplier to be used on the base number to find the actual value of the capacitor. Use a third digit of 0 through 5 to place the corresponding number of 0s behind the base value.

If you have more questions about bulk capacitors, you can search for the product website and ask for professional help.

The End

As an indispensable component in the electronic field, bulk capacitors play an important role in power management and signal processing. With the continuous progress of technology, we have reason to believe that the future of large-capacity capacitors will be more efficient and stable, and provide more powerful support for the performance improvement of electronic devices.

Disclaimer: The views and opinions expressed by individual authors or forum participants on this website do not represent the views and opinions of Chipsmall, nor do they represent Chipsmall's official policy.

share this blog to: