OUTLINE:

5 Steps: How to Combine NonPolar Capacitors?

226

226Don't know how to combine nonpolar capacitors? Never mind, this article will teach you step by step (suitable for green hand) and finally you will get a combined nonpolar capacitor with little effort. By strategically combining nonpolar capacitors, you can tailor the capacitance values to meet specific requirements in electronic circuits, ensuring optimal performance and functionality. You need to follow the 5 steps given below and the thing will be done.

What Are NonPolar Capacitors

Before we combine nonpolar capacitors, we need to have a clear mind about what they are.

Capacitors

Capacitors are electronic components used to store and discharge electrical energy. Capacitance determines a capacitor's ability to retain charge, with larger capacitance signifying better charge storage capacity.

NonPolar Capacitors

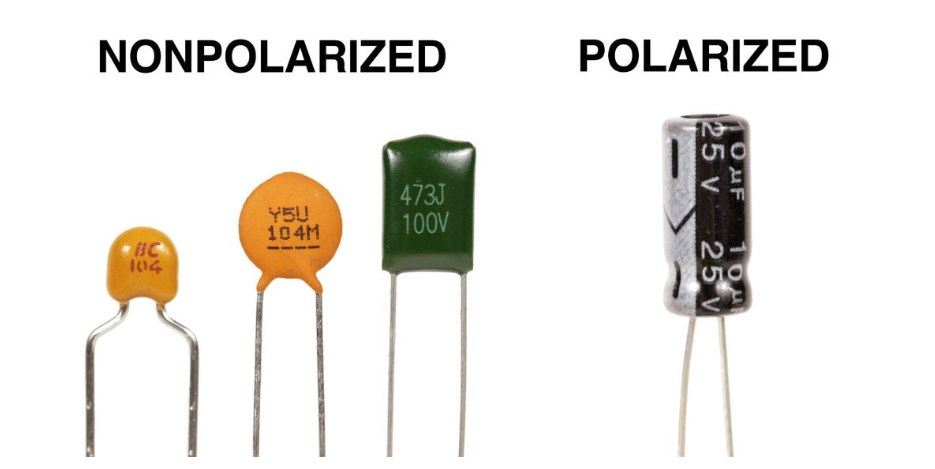

Capacitors with neither positive nor negative polarity are known as non-polarized capacitors.

Non-polarized capacitors' two electrodes can be put into the circuit at random and will not leak. In addition, polar and nonpolar capacitors have different functions and there are several types of combinations of nonpolar capacitors.

1. Functions of Polar and NonPolar Capacitors

Both polar and non-polar capacitors serve the same fundamental function: storing electrical energy in an electric field. However, they differ in their construction, polarity, and applications.

Here are the key functions of polar capacitors:

- Store energy in DC circuits: Polar capacitors are primarily used in DC circuits where the voltage across the capacitor remains constant. They are used in various applications, including power supplies, filters, and timing circuits.

- Smoothing voltage: Polar capacitors can store energy and release it slowly, helping to smooth out fluctuations in the voltage supply.

- Coupling and decoupling: Polar capacitors can be used to couple AC signals from one stage of a circuit to another while blocking DC signals. They can also be used to decouple power supply noise from sensitive circuits.

Here are the key functions of non-polar capacitors:

- Store energy in AC and DC circuits: Non-polar capacitors can be used in both AC and DC circuits, making them more versatile than polar capacitors.

- Filtering: Non-polar capacitors can be used to filter out unwanted frequencies from AC signals.

- Tuning circuits: Non-polar capacitors are used in tuned circuits, such as those found in radios and televisions, to select specific frequencies.

- Types of Combinations of NonPolar Capacitors

Non-polar capacitors offer versatility due to their lack of polarity, allowing them to be combined in various ways to achieve desired capacitance and voltage ratings. The three main types of combinations are parallel combination, series combination, and mixed combination.

Types of NonPolar Capacitors

Non-polar capacitors are further separated into two sections. So we find two typical forms of non-polar capacitors.

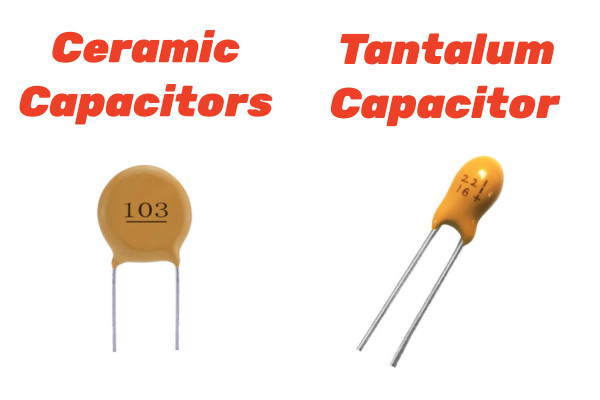

Ceramic capacitors:

These are utilized in high-frequency appliances. They are little and light. Furthermore, these are relatively inexpensive. Despite their tiny size, they can conduct a large amount of electricity. As a result, they are commonly utilized in big appliances.

Tantalum capacitor:

These capacitors are employed in appliances with limited space because of their high density. These are for appliances that produce a large amount of heat. The most typical application for these capacitors is in audio equipment.

How to Combine NonPolar Capacitors

Unlike polar capacitors, which have particular polarity requirements, nonpolar capacitors provide greater freedom in connection and may be coupled in a variety of topologies. This provides chances to modify capacitance levels to satisfy specific circuit needs. Understanding how to combine nonpolar capacitors is vital, whether you want to enhance total capacitance or build bespoke capacitance values. Here's a guide to help you through the process.

1. Gather materials

- Non-polar capacitors with desired capacitance values and voltage ratings.

- Soldering iron and solder (for permanent connections).

- Wire strippers and cutters.

- Heat shrink tubing (optional, for insulation).

- Multimeter (optional, for testing).

2. Determine your desired capacitance and voltage rating

- Calculate the total capacitance required for your circuit.

- Decide whether you need to increase the voltage rating or maintain the individual capacitor rating.

3. Choose the combination type

- Parallel: Use this for increasing total capacitance while maintaining voltage rating.

- Series: Use this for increasing voltage rating while maintaining or decreasing capacitance.

- Mixed: Combine both methods for customized capacitance and voltage rating.

4. Connect the capacitors

- For parallel connection, connect the positive leads together and the negative leads together.

- For a series connection, connect the positive lead of one capacitor to the negative lead of the other.

- Use solder or other secure connections depending on your application.

5. Insulate and test the connections

- Cover the connections with heat shrink tubing or other insulating material for safety.

- (Optional) Use a multimeter to check the total capacitance and voltage rating of the combined capacitors.

Additional Tips and Safety Precautions

By following the steps and taking necessary precautions, you can safely and effectively combine non-polar capacitors to meet your specific circuit requirements:

- Use capacitors with similar voltage ratings and dielectric materials for optimal performance.

- Ensure proper polarity for each capacitor within the combination.

- Double-check your connections for any short circuits or loose wires.

- Test your circuit carefully after combining the capacitors.

- Always discharge any capacitors before handling them.

- Use proper tools and techniques to avoid electrical shock or damage.

- Choose capacitors with appropriate voltage ratings for your application.

Can I use non-polarized capacitors instead of polarized capacitors

Ideal capacitors are originally non-polar. However, in reality, in order to obtain large capacity, some special materials and structures are used, which leads to the fact that some actual capacitors are polar. Common polar capacitors include aluminum electrolytic capacitors, tantalum electrolytic capacitors, etc. Electrolytic capacitors generally have relatively large capacity. If you want to make a large-capacity non-polar capacitor, it is not so easy, and the volume will become very large. This is why there are so many polar capacitors in actual circuits-because it is relatively small, and because the voltage in such a circuit has only one direction, polar capacitors can come in handy. We use polar capacitors to avoid its shortcomings and take advantage of its advantages. We can understand it this way: a polar capacitor is actually a capacitor that can only be used in one voltage direction. A non-polar capacitor can be used in both voltage directions. Therefore, from the perspective of voltage direction alone, a non-polar capacitor is better than a polar capacitor.

From the above analysis, it can be seen that it is completely possible to use a non-polar capacitor instead of a polar capacitor-as long as the capacity, working voltage, volume, etc. meet the requirements.

The end

Combining non-polar capacitors offers a versatile solution to achieving specific capacitance and voltage requirements in your electronic projects. This article equipped you with the knowledge and practical steps to confidently combine non-polar capacitors, ensuring optimal performance and safety.

Remember to choose appropriate capacitors, connect them correctly, and validate their functionality for a successful outcome. Now, if your friends ask you how to combine nonpolar capacitors, just send them this article!

Disclaimer: The views and opinions expressed by individual authors or forum participants on this website do not represent the views and opinions of Chipsmall, nor do they represent Chipsmall's official policy.

share this blog to:

Relevant Parts for Sale

EKZH160ELL222MK20S

2200uF ±20% 16V 12.5x20 6000Hrs @ 105℃ 2.48A @ 100kHz Radial,12.5x20mm Aluminum Electrolytic Capacit