OUTLINE:

A Comprehensive Guidance for Circuit Card Assembly

100

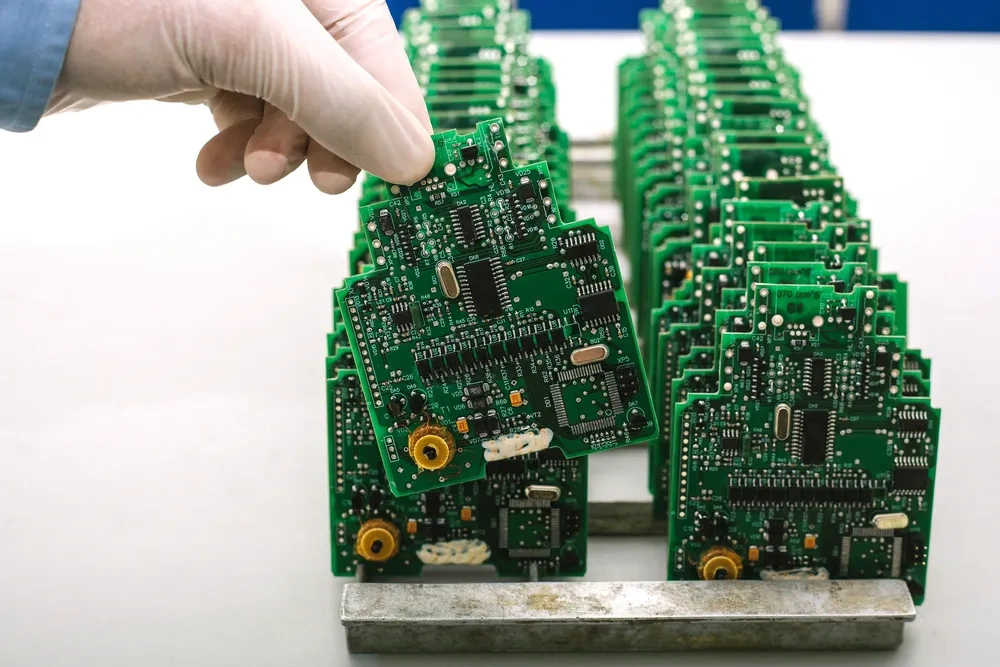

100Putting together a Circuit Card Assembly (CCA) isn’t just about slapping parts onto a board—it’s about making sure everything runs smoothly and lasts.

Image Source: PS Electronics

Whether you're working on everyday electronics or something more high-tech, getting it right from the start is key. From picking the right components to soldering and testing, every step matters. In this guide, we’ll break it all down in a super simple, step-by-step way so you can build a reliable circuit card assembly without the headache.

What Is A Circuit Card Assembly

A Circuit Card Assembly (CCA) is basically a Printed Circuit Board (PCB) with all its electronic components attached and ready to do its job. It’s the brain behind all kinds of electronics, from smartphones to aerospace systems. Unlike a bare PCB, which is just a board with copper traces, a CCA has everything mounted—resistors, capacitors, chips, connectors—so it can function as part of a larger system. These assemblies go through processes like soldering, testing, and quality checks to make sure they work reliably. Whether it’s for a simple gadget or a complex industrial machine, a well-made CCA is what keeps electronics running smoothly.

The necessary Components for Circuit Card Assembly

Image Source: Wevolver

A Circuit Card Assembly (CCA) is basically a working circuit board with all the parts it needs to do its job. Here are the key components that bring it to life:

Printed Circuit Board (PCB) – The base of everything, with copper pathways connecting all the parts.

Resistors – Keep electrical current under control so nothing burns out.

Capacitors – Store and release energy to keep power steady and signals clean.

Inductors – Help manage electrical flow, especially in power circuits.

Diodes – Act like one-way doors for electricity, stopping it from going the wrong way.

Transistors – Tiny but powerful switches that control signals and power.

Integrated Circuits (ICs) – The “brains” of the board, handling everything from processing to memory.

Connectors – Let the board hook up to other components, wires, or even other circuit boards.

Relays – Work as electric switches to control bigger currents.

Oscillators & Crystals – Keep timing accurate for processors and communication systems.

The Role of Circuit Card Assembly in Modern Electronics

That circuit card assembly (CCA) is really important in our current electronic products! It's like a place where electronic gadgets stand in line and play games hand in hand. From the electrical appliances in our home to the large machines in the factory, CCA plays a significant role in making these things run. Let's chat together about how awesome it really is:

The 'home' of components

CCA is like finding a stable place for important components such as microchips, resistors, capacitors, and connectors. They are all welded and lined up on top, so that electrical signals can flow smoothly and our electronic devices can work properly.

Small stature, great wisdom

The development of CCA has made our electronic products smaller and more refined. It can make those components tightly packed without losing order, so we can use smaller and more powerful devices. Look at that phone, laptop, and those small things that can be worn on the body, they all rely on it.

Signal not lost

The circuit card components are ingeniously designed to ensure that signals do not lose or weaken. In this way, high-performance electronic products can run faster and more steadily. The wiring and layout must be just right, without causing interference to the signal or losing it.

Save money and be efficient

Now with automated assembly technology, such as surface mount technology (SMT), making CCA has become both cost-effective and efficient. These technologies can make production faster, more consistent, and employ fewer people, making it much easier to expand production.

Durable and sturdy

CCA is made particularly sturdy, making the equipment not afraid of falling, heat, moisture, or vibration. They all have to go through a series of tests to ensure that they can work well in various harsh environments. This is simply too important for people who make cars, airplanes, and telecommunications.

Change whatever you want

Nowadays, many electronic products require customized CCA to meet various special needs. Whether it's the machines we use at home, in hospitals, or in factories, CCA can be designed in various shapes and equipped with different components to achieve various functions according to our needs.

A great helper for high-tech

CCA is still a good helper for high-tech industries such as the Internet of Things, robots, artificial intelligence, and 5G communication. It can make complex circuits small and delicate, and also connect them to meet our needs for smart devices and systems.

Environmental protection expert

Nowadays, everyone is concerned about environmental protection, and manufacturers have come up with many ways to make CCA more environmentally friendly. They use lead-free solder and recyclable materials, so that the electronic products they produce can meet regulations and make us feel environmentally friendly.

Different Types of Circuit Card Assemblies

Circuit Card Assemblies (CCAs) come in various types, each tailored to specific applications and manufacturing requirements. The type of CCA chosen depends on factors such as the complexity of the circuitry, component density, and the intended use of the electronic device. Below are the different types of circuit card assemblies:

1. Single-Sided Circuit Board (SSB)

Description: In a single-sided CCA, all components are mounted on one side of the board. The other side is usually left free of components, serving as a means to connect the components via conductive traces.

Applications: This type of CCA is used for simpler and less complex designs, such as low-cost consumer electronics, power supplies, and basic devices.

Advantages: Easy to manufacture, lower cost, and simple design.

Limitations: Limited component density and functionality compared to more advanced CCAs.

2. Double-Sided Circuit Board (DSB)

Description: Double-sided CCAs allow components to be mounted on both sides of the board, with electrical connections made via vias (holes) that connect the two sides.

Applications: Common in more complex devices like printers, industrial machines, and consumer electronics that require more space for components.

Advantages: More components can be added, increasing the functionality while maintaining a compact design.

Limitations: More complex manufacturing process than single-sided boards。

3. Multi-Layer Circuit Board (MLB)

Description: Multi-layer CCAs consist of multiple layers of PCB (printed circuit board) stacked and interconnected, allowing for high-density component placement and better signal routing. These boards typically have 4, 6, or more layers of conductive material, with insulating layers between them.

Applications: Found in high-performance electronics such as smartphones, computers, medical devices, telecommunications equipment, and aerospace applications.

Advantages: High-density component placement, improved signal integrity, and reduced board size.

Limitations: More expensive to manufacture and requires specialized assembly processes.

4. Flexible Circuit Boards (Flex PCBs)

Description: Flexible CCAs are made from flexible materials like polyimide or polyester, allowing the board to bend and conform to different shapes. They are often used in applications where space is constrained or where the device needs to be lightweight and flexible.

Applications: Used in wearable electronics, automotive systems, medical devices, and portable consumer gadgets.

Advantages: Can be bent, folded, and twisted without breaking, saving space and allowing for compact designs.

Limitations: More expensive than rigid boards and may have a lower component density.

5. Rigid-Flex Circuit Boards

Description: These boards combine the benefits of both rigid and flexible circuit boards. They have sections that are rigid for structural stability and other parts that are flexible, providing design flexibility.

Applications: Common in high-tech industries such as aerospace, military, medical equipment, and consumer electronics (e.g., smartphones, cameras).

Advantages: Can achieve compact and lightweight designs with higher performance, integrating both rigid and flexible features in one package.

Limitations: More costly to manufacture and design, as they combine the complexity of both rigid and flexible boards.

6. High-Density Interconnect (HDI) Circuit Boards

Description: HDI boards feature high-density wiring and more advanced manufacturing techniques, such as microvias (very small vias), finer traces, and advanced materials. These boards enable higher functionality and performance in a smaller form factor.

Applications: Used in cutting-edge technologies like smartphones, tablets, wearables, high-end computers, and automotive electronics.

Advantages: High-density components, smaller size, and improved performance. Offers greater functionality in a compact space.

Limitations: More expensive and difficult to manufacture.

7. Aluminum-Based Circuit Boards

Description: Aluminum-based CCAs are designed for applications that generate significant heat. The base material is usually aluminum, which provides efficient heat dissipation.

Applications: Common in LED lighting, power supplies, automotive systems, and other heat-sensitive electronics.

Advantages: Excellent thermal management, durable, and reliable under high-temperature conditions.

Limitations: Heavier than traditional PCBs, and more expensive.

8. Thick Film Hybrid Circuit Boards

Description: These CCAs are created using a thick film process, where conductive traces are printed onto a substrate, usually ceramic or metal, and then components are attached. They are used for applications requiring high power handling and environmental stability.

Applications: Used in power supplies, sensors, automotive applications, and some industrial electronics.

Advantages: Can handle high voltages and power, good thermal performance, and stability under harsh conditions.

Limitations: More costly and typically used for specific industrial applications.

9. Chip-on-Board (COB)

Description: In COB assembly, bare microchips are directly attached to the surface of the circuit board, bypassing traditional packaging. This reduces the overall size and improves performance.

Applications: Used in LED lighting, medical devices, and other applications where miniaturization and performance are critical.

Advantages: Smaller, faster, and lower cost due to the absence of traditional packaging.

Limitations: Limited to specific applications and may require additional protective coatings.

What Is the Difference between A PCB and A CCA(Circuit Card Assembly)

Image Source: Wevolver

A PCB (Printed Circuit Board) is the bare board made from a non-conductive material, typically fiberglass or epoxy, with conductive pathways (traces) that connect various components. It serves as the foundation for mounting electronic components but doesn't include any parts or connections yet.

On the other hand, a CCA (Circuit Card Assembly) refers to a fully assembled PCB, where all the required electronic components, such as resistors, capacitors, diodes, and microchips, are mounted and soldered onto the board. The CCA is the functional unit that can be integrated into electronic devices, whereas the PCB is just the starting point of the assembly process.

In summary, the PCB is a blank board with traces for component placement, while the CCA is the completed board with all components and soldering, ready for use in a finished product.

The End

Achieving excellence in Circuit Card Assembly (CCA) requires careful attention to design, materials, component placement, and assembly techniques. By following a structured, step-by-step approach, manufacturers can ensure high-quality CCAs that meet performance, reliability, and cost-efficiency standards, ultimately contributing to the success of the final electronic product.

Disclaimer: The views and opinions expressed by individual authors or forum participants on this website do not represent the views and opinions of Chipsmall, nor do they represent Chipsmall's official policy.

A Comprehensive Guidance for Circuit Card Assembly

share this blog to: