OUTLINE:

The Most Comprehensive Guide to Air Compressor Pressure Switch

97

97In the air compressor field, pressure switches are primarily used to monitor and regulate system pressure to maintain equipment safety and efficiency. They're commonly utilized in air compressors, refrigeration compressors, and other applications.

What Is An Air Compressor Pressure Switch

The application of pressure switches in the field of air compressors is very common, but what are the specific applications of pressure switches in the air compressor industry? Today, I will give you a brief introduction.

Air Compressor

An air compressor is a basic product of industrial modernization. The term electrical and automation often refers to pneumatics. An air compressor is the core equipment of a pneumatic system and is the main body of an electromechanical air source device. It often converts the motive force of an electric motor into gas pressure energy and is a compressed air pressure generating device. To ensure proper functioning of the air compressor and to regulate the generated pressure, a mechanism is required to monitor and control these pressure levels.

Pressure Switch in Air Compressor

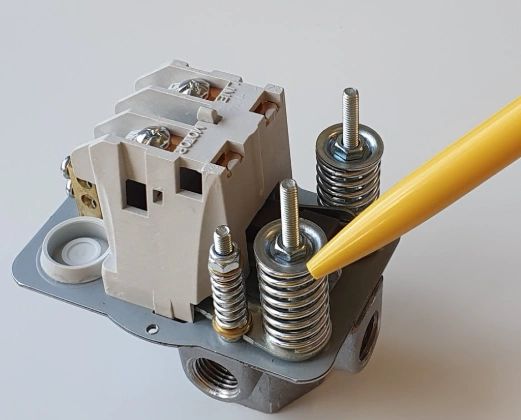

An air pressure switch is a mechanical device that uses pressure to control the operation of an electric air compressor. The device's air pressure circuit mechanism provides power to the motor, allowing it to work. By maintaining appropriate pressure levels, the air pressure switch ensures that the compressor operates within the desired parameters, preventing over-pressurization or insufficient pressure.

The air compressor's pressure switch includes a pressure switch relief valve. This valve serves as a safety feature, allowing excess pressure to be released when needed, safeguarding the system from potential damage.

Know more information about pressure switch symbol.

Air compressor pressure switches use air lines to monitor pressurized air entering and exiting your air tank. Every pressure switch has an element that responds when pressure is applied to it. The most common variety is a diaphragm, which deforms or compresses in response to compressed air.The most common of these components is a diaphragm, which deforms or compresses when subjected to pressurized air.

Function of the Pressure Switch in An Air Compressor

The pressure switch is used on the air compressor to adjust the start and stop state of the air compressor. By adjusting the pressure in the air tank, the air compressor can be stopped and rested, which has a maintenance effect on the machine. For example, the compressor starts to start and fills the air tank with air. When the pressure reaches 10kg, the air compressor stops or unloads. When the pressure reaches 7kg, the air compressor starts again. There is a pressure difference during this process. This process can let the compressor rest and achieve the purpose of protecting the air compressor.

What Happens When A Pressure Switch Fails

When the pressure switch of the compressor fails, the following may occur:

Unable to start or stop: Failure of the pressure switch may cause the compressor to be unable to stop when the set pressure is reached, resulting in continuous overpressure, increasing equipment load and energy consumption; or it may be unable to start when the pressure is insufficient, causing the system to fail to work properly.

Equipment damage: If the pressure switch cannot cut off the power supply, the compressor may be damaged due to long-term overpressure operation, or even cause mechanical failure or motor burnout.

Safety hazards: Overpressure operation may cause pipelines or gas tanks to burst, posing serious safety hazards and may cause accidents.

Reduced efficiency: Failure of the pressure switch may cause the compressor to start and stop frequently or fail to reach the required pressure, affecting system efficiency and production processes.

Therefore, regular inspection and maintenance of pressure switches are the key to ensuring safe and efficient operation of compressors.

How Do I Know If My Air Compressor Pressure Switch Is Bad

Like any equipment, the air compressors may develop problems with time. The pressure switch is a common source of problems. This critical component contributes to the control of the compressor's air pressure output. When these situation occurs, you should pay more attention to your device.

Fail to cut out

One of the most obvious indicators of a faulty pressure switch is when the air compressor fails to cut out when it should or shuts down before achieving the necessary PSI (pounds per square inch). When the air tank hits the specified pressure limit, the pressure switch should immediately turn off the motor. If the compressor continues to operate after reaching this limit or shuts off prematurely, it indicates a faulty pressure switch.

Fail to turn on or cut in

If your compressor fails to turn on or cut in when the tank pressure drops below a certain level, it could be due to a faulty pressure switch. The switch is responsible for starting the motor when the tank pressure drops below a certain level.

Abnormal noise

If you hear weird noises from your air compressor, do not disregard them. Strange sounds frequently indicate mechanical problems. A faulty pressure switch may make strange noises while operating. If you hear similar sounds, have a professional inspect your compressor.

Broken knob or switch

Physical damage to the pressure switch can also result in difficulties. A broken knob or switch is a clear indication that you should replace the complete pressure switch unit. Inspect your compressor on a regular basis to spot such faults early and avoid further damage or complications.

Rust

Rust on the pressure switch is not a good indicator. It not only signifies potential water damage, but it can also interfere with the switch's operation. If you see rust, consider replacing the switch to avoid more serious problems down the road. Regularly inspecting and servicing your portable air compressor can allow you to spot problems early and extend the life of your equipment.

Unloader/Bleeder valve leaks

Many pressure switches have a straight or 90-degree unloader (or bleeder) valve on the bottom or side, where a small airline (usually ¼") connects. A leak here typically indicates a faulty unloader valve or in-tank check valve, not a faulty pressure switch.

Where to Buy Pressure Switches

Advance Controls, Inc

Advance Controls, Inc. is a leading manufacturer of high-quality pressure switches, pressure transducers, and associated equipment. For over 35 years, the company has served the industrial and commercial markets, earning a reputation for innovative products and excellent customer service.

Advance Controls provides a diverse line of pressure switch devices, including electromechanical, solid-state, and electronic switches, for a number of applications. Their switches are utilized in a variety of industries, including HVAC, water treatment, oil and gas, food and beverage, and more.

Custom Control Sensors

Custom Control Sensors is a leading manufacturer of innovative sensing and control solutions for a wide range of industries. Custom Control Sensors provides a comprehensive assortment of pressure switches designed to fulfill the needs of a variety of industries and applications. Their pressure switches are utilized in a variety of industries, including HVAC, refrigeration, oil and gas, and water treatment. They provide a wide range of switch types, including differential pressure switches, vacuum switches, and high-pressure switches, to mention a few.

Delta Controls Corporation

Delta Controls Corporation is a prominent manufacturer of high-quality pressure switches, temperature switches, differential pressure switches, and flow switches for use in a variety of sectors, including oil and gas, chemical, electricity, and water.

Delta Controls' pressure switches are internationally certified for usage in hazardous environments for safety purposes.

Chipsmall Limited

Chipmall Limited is a leading supplier of semiconductor components and packaging solutions, serving customers worldwide in various industries such as electronics, automotive, telecommunications, and more. Chipsmall has created an online mall where you can see product price trends, wholesale prices, x-ray test reports, and other information on the product page.

Chipsmall provides different switch products, and customers can find the switch they need by filtering.

.webp)

Disclaimer: The views and opinions expressed by individual authors or forum participants on this website do not represent the views and opinions of Chipsmall, nor do they represent Chipsmall's official policy.

share this blog to: