OUTLINE:

How to Replace a Thermostat Sensor

196

196Temperature sensors are widely used in the automotive industry today. Common temperature sensors found in commercial vehicles include ambient temperature sensors, coolant temperature sensors, intake air temperature sensors, and oil temperature sensors. Let's learn about the coolant thermostat sensor today!

Image Source: Pep Boys

What is a Coolant Thermostat Sensor

Coolant temperature sensors play a pivotal role in maintaining optimal engine performance and preventing overheating incidents. These sensors are strategically positioned within the vehicle's cooling system to ensure accurate temperature readings. Their precise measurements enable the engine control unit (ECU) to make real-time adjustments to fuel injection timing, air-fuel ratio, and ignition timing, thus optimizing combustion efficiency and reducing emissions.

Where are Coolant Thermostat Sensors Usually Installed

The sensor is generally installed in the cylinder water channel, cylinder head water channel, water outlet pipe, etc., and is in contact with the coolant. The ECU adjusts fuel injection timing and ignition timing based on this temperature signal.

Image Source: Grimmer Motors

How Does a Coolant Thermostat Sensor Work

Inside the coolant thermostat sensor is a semiconductor thermistor with a negative temperature coefficient NTC.

To obtain an accurate reading of the current engine temperature, the ECU transmits a regulated voltage to the CTS. The resistance of the sensor fluctuates with temperature, which allows the ECU to detect temperature changes. The ECU utilizes this reading to compute the coolant temperature, then changes the fuel injection, fuel mix, and ignition timing, as well as controlling when the electric cooling fan is turned on and off. This information is also used to provide an accurate measurement of the engine temperature to a dashboard gauge.

How to Spot a Faulty Coolant Thermostat Sensor

Coolant thermostat sensors are instrumental in safeguarding the engine from potential damage caused by extreme temperatures. By continuously monitoring coolant temperature levels, these sensors provide early warnings of overheating conditions, allowing drivers to take preventive measures promptly.

A malfunctioning coolant temperature sensor can lead to various engine performance issues. If you experience any of these symptoms, it is important to have your vehicle thoroughly inspected to address potential problems related to the coolant temperature sensor.

Overheating Engine: If your engine consistently overheats, it could be due to a coolant temperature sensor that is transmitting incorrect hot signals to the computer. This can cause the engine to misfire or overheat.

Image Source: innova

Poor Fuel Economy: A faulty coolant temperature sensor can send inaccurate signals to the computer, leading to unbalanced timing and fuel calculations. This can result in poor fuel efficiency and increased fuel consumption.

Check Engine Light: If the "Check Engine" light illuminates on your dashboard, it could indicate a problem with the coolant temperature sensor. The computer may detect issues with the sensor's circuit or signal and trigger the warning light.

Black Smoke Emitted from the Engine: A malfunctioning coolant temperature sensor can cause the computer to enrich the fuel mixture unnecessarily. This can lead to incomplete combustion and the emission of black smoke from the exhaust pipe.

Poor Idling: A faulty coolant temperature sensor can cause the engine's fuel mixture to be improperly adjusted, resulting in engine shaking, vibrations, or strange behaviors, particularly at low speeds or during idle.

Defective Electrical Cooling Fans: In some vehicles, the coolant temperature sensor controls the electric cooling fans. If the sensor fails, the fans may not function properly, potentially leading to inadequate cooling of the engine.

At the same time, regular inspection of the coolant temperature sensor is also necessary to avoid failure. Its normal operation has an important impact on engine performance and economy.

How to Replace a Coolant Temperature Sensor

Replacing a faulty coolant temperature sensor is a relatively straightforward process that can be done by following these steps:

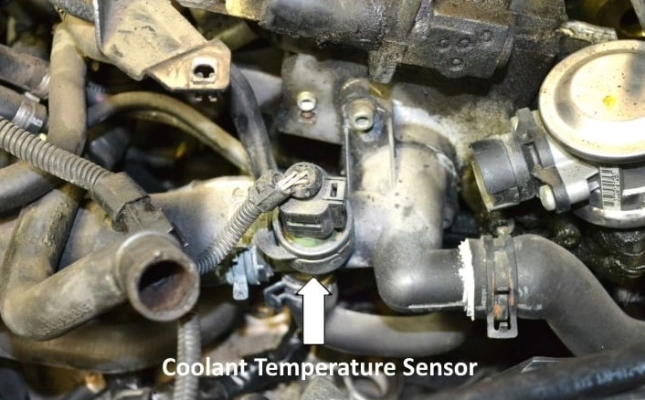

Locate the Sensor: The coolant temperature sensor (CTS) is typically found near the front of the engine, close to the radiator or thermostat housing. You may need to use a light or remove the engine cover to locate it properly.

Remove the Connector Cable: Carefully disconnect the connector cable that links the CTS to the engine control unit (ECU). Take care not to break the plastic connector or wiring during this step.

Loosen and Remove the Old Sensor: Using a deep socket and ratchet, loosen the sensor in an anticlockwise direction. Apply gentle pressure and consider using a release spray if the sensor is stuck. Once loose, unscrew it by hand and be prepared for coolant leakage.

Install the New Sensor: Clean the area around the socket using a cloth to remove any debris. Place the new sensor in the threads and twist it clockwise by hand, ensuring it is securely seated. Finally, use a torque wrench to tighten the sensor to the specified torque value.

Reinstate the Connector Cable: Ensure the connector is clean and free from debris, then carefully plug it into the new sensor. Tighten any clips to ensure a secure connection. Start the engine and monitor the temperature gauge to verify proper functioning.

How Much Does an Coolant Thermostat Sensor Replacement Cost

The cost of replacing your coolant thermostat sensor is normally in the range of $200 to $400. Included in this are the labor costs, which often range from $100 to $150, and the parts costs, which typically range from $5 to $250. Your vehicle's make, model, and the location of the repair shop will determine the precise cost.

Purchase your sensor from Chipsmall, where we provide sensor choices for almost all makes and models.

Conclusion

Overall, the reliability and accuracy of coolant thermostat sensors are paramount for the smooth operation and longevity of modern automotive engines. Regular maintenance and timely replacement of faulty sensors are essential to avoid potential breakdowns and ensure optimal vehicle performance and safety.

Disclaimer: The views and opinions expressed by individual authors or forum participants on this website do not represent the views and opinions of Chipsmall, nor do they represent Chipsmall's official policy.

share this blog to: