OUTLINE:

What Does Feedback Knock Actually Mean

155

155It may have happened on your trip that you heard a knocking sound in your vehicle's engine. While there are varied levels of severity, one thing stays constant: it is a condition that must be addressed immediately by a professional. This can be dangerous because it can cause engine damage if left untreated. In this article, we will take you through the meaning of feedback knock, the causes behind it, and how to troubleshoot this issue effectively.

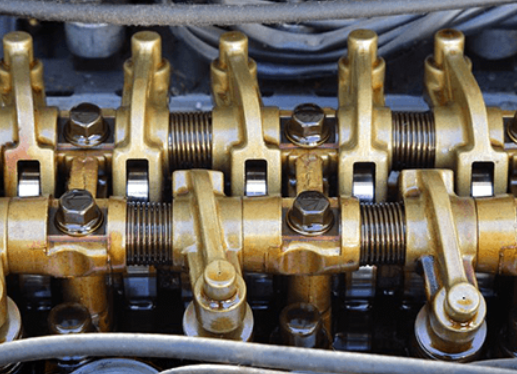

What is Feedback Knock in an Engine

The term "feedback knock" refers to a knock detected by the knock sensor and 'fed back' to the engine management system. It is often produced by cylinder pre-ignition or detonation before the piston reaches the peak of the compression stroke.

Is Feedback Knock Bad

Yes, feedback knock is generally considered bad for an engine. It can lead to various negative effects, including reduced engine performance, decreased fuel efficiency, and potential damage to engine components. Prolonged exposure to feedback knock can cause piston damage, cylinder wall scoring, and even engine failure if left unresolved.

What Causes Feedback Knock

We'll go over five of the most typical reasons you might hear your engine knock.

Low-quality or improper fuel: Using fuel with a lower octane rating than what is recommended by the manufacturer can increase the likelihood of feedback knock.

Overheating: High engine temperatures can promote pre-ignition of the air-fuel mixture, leading to feedback knock.

Spark timing issues: Incorrect ignition timing can cause the fuel to ignite at the wrong moment, resulting in feedback knock.

Carbon deposits: The accumulation of carbon deposits on the pistons or cylinder walls can create hot spots, promoting feedback knock.

Engine modifications: Aftermarket modifications, such as turbochargers or superchargers, can alter the engine's dynamics and increase the risk of feedback knock if not properly tuned.

How to Troubleshoot Feedback Knock

If you suspect feedback knock in your engine, it is crucial to address the issue promptly to prevent further damage. Here are some troubleshooting steps to consider:

Use high-quality fuel: Ensure that you are using fuel with the recommended octane rating for your engine. Higher octane fuel has better resistance to knock.

Check spark plugs and ignition system: Inspect and replace worn-out spark plugs, ignition coils, or spark plug wires if necessary. Faulty ignition components can contribute to feedback knock.

Monitor engine temperature: Keep an eye on the engine's temperature to prevent overheating. Ensure that the cooling system is functioning correctly and that coolant levels are adequate.

Clean carbon deposits: If carbon buildup is suspected, consider using fuel additives or having a professional clean the intake valves, pistons, and combustion chambers.

Compression test: Perform a compression test to check the health of the engine's cylinders. Low compression in one or more cylinders can cause knocking and may indicate a more serious issue, such as worn piston rings or cylinder wall damage.

Understanding Knock vs. Ping in Engines

Knock (Detonation): Feedback knock, or detonation, occurs when the air-fuel mixture in the engine's cylinders ignites prematurely, before the spark plug ignites it. This can happen due to high temperatures or pressures within the cylinder, or if the fuel has a low octane rating. Knocking can cause a loud, metallic tapping noise and, if severe, can lead to engine damage.

Ping (Pre-ignition): Ping is a less severe form of knock, where the air-fuel mixture ignites slightly earlier than intended, but after the spark plug has already fired. This is often caused by hot spots in the combustion chamber, such as carbon deposits or a worn spark plug. While less damaging than knock, ping can still reduce engine efficiency and power.

Conclusion

Feedback knock in engines is a concerning condition that can negatively impact engine performance and longevity. Understanding its causes and implementing effective troubleshooting measures, such as using high-quality fuel, maintaining proper ignition timing, and addressing carbon deposits, can help mitigate the risk of feedback knock. By taking proactive steps, you can ensure the smooth operation and longevity of your engine while avoiding potential damages associated with feedback knock.

Disclaimer: The views and opinions expressed by individual authors or forum participants on this website do not represent the views and opinions of Chipsmall, nor do they represent Chipsmall's official policy.

share this blog to: