OUTLINE:

Find Cable Faults and Locating Them

267

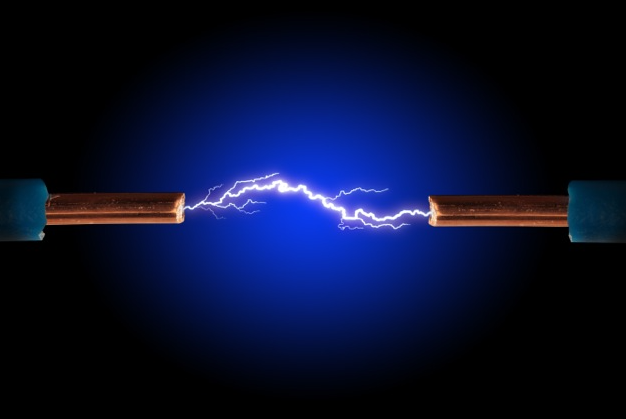

267Are you interested in learning about cable faults and how to locate them? Faults in electrical cables can cause disruptions in power distribution and can be challenging to locate. There are several types of cable faults, including open-circuit faults, short-circuit or cross faults, and ground or earth faults.

Open-circuit faults occur when the conductor breaks or is pulled out of its joint, resulting in no flow of current. Short-circuit or cross faults happen when the insulation between two cables or multi-core cables is damaged, causing the current to flow directly from one cable to another and short-circuiting the load. Ground or earth faults occur when the cable insulation is damaged, causing the current to flow from the core of the cable to earth or the cable sheath instead of through the load.

Cable faults are often caused by dampness in the paper insulation of the cables, which can damage the lead sheath protecting the cable. The lead sheath can also be damaged by the chemical action of soil, mechanical damage, or crystallization through vibration.

To locate cable faults, the fault must first be identified. There are several ways to find cable faults, including visual inspection, cable testing, and fault location methods such as time domain reflectometry (TDR) or acoustic techniques. It's important to identify and locate cable faults as quickly as possible to minimize disruptions in power distribution.

Cable fault location is a complex process that requires a series of steps to be performed safely and as quickly as possible to minimize customer outages. The process starts with cable isolation and safety procedures, where the cable is made safe by isolating and then earthing one or both ends. This is followed by cable identification testing to identify the correct cable to work on, especially in cases where multiple cables exist. Clear identification before a cable is cut is intrinsic to safe maintenance work, and any mistakes here can be fatal and may cause much longer outages for the connected customers.

The cable tracing step is equally important to determine the route of the cable, which can meander in depth and direction when first laid underground. Fault identification is another critical step, where the phase on which the fault has occurred is determined, and if it is of low or high resistance. This test determines the correct technique and equipment to diagnose the fault, with low voltage pulse and impulse generator being the primary techniques used.

Fault prelocation is also essential to locate a cable fault quickly and efficiently. Good pre-location can determine the fault position to within a few percent of the cable length and will reduce pinpointing time to a few minutes. For low resistance faults, pre-location is likely the only means necessary for location, while high resistance faults require ARM or ICE techniques on an SWG or the decay method with an HV DC tester.

Finally, pinpointing is the last step in the cable fault location process, where acoustic pinpointing techniques must be employed to narrow the margin of error to 0.1%. Shock discharge generators are used for pinpointing in conjunction with acoustic methods to create a loud noise that is pinpointed precisely using an acoustic pinpointing device. The device evaluates the time difference between the acoustic signal and the electromagnetic impulse of the shock discharge to reveal the exact fault location.

Disclaimer: The views and opinions expressed by individual authors or forum participants on this website do not represent the views and opinions of Chipsmall, nor do they represent Chipsmall's official policy.

share this blog to: