OUTLINE:

A Comprehensive Introduction of Flyback Transformer [For Beginners]

208

208Are you a novice in the field of electronics and quite interested in the operation of flyback transformers?

Image Source: everything PE

Whether you enjoy making small things with your hands or just want to know how electricity is converted, this guide can help you. We will use plain language to explain to you the main functions and components of the flyback transformer, as well as how it is used in various places, so that you can understand at a glance how these small things make our electronic devices run so well. Let's explore the world of flyback transformers together!

Quick View: What Is A Flyback Transformer

Image Source: Wikipedia

Flyback transformer is a type of transformer commonly used in power supplies, especially in situations where small size and high voltage conversion are required. It works based on the principle of magnetic energy storage and transmission. Can you briefly describe its characteristics

Key features

Energy storage: The flyback transformer stores energy in the magnetic field in the "on" state (when the primary side is powered on), and then releases it in the "off" state (when the primary side is powered off). In this way, it can achieve electrical isolation and voltage conversion.

High efficiency: Flyback transformers are particularly efficient in converting high voltage DC to low voltage DC, or vice versa, so they are often used in power supplies for televisions, displays, and other electronic devices.

Working principle

The primary winding of the transformer is powered by a switching transistor (usually a MOSFET or bipolar transistor).

As soon as the switch is turned off, the magnetic field collapses, inducing a voltage on the secondary winding. After rectification and stabilization, this voltage can supply power to the load.

Application scenarios: Flyback transformers are common in switch mode power supplies (SMPS), televisions, computer monitors, and inverters.

Advantage

Small size: suitable for applications with limited space.

Low cost: Compared to other transformers of the same power level, the price is more affordable.

Electrical isolation: It can provide electrical isolation between input and output, improving the safety of high-voltage applications.

The Function of A Flyback Transformer in A CRT

In the cathode ray tube (CRT) televisions or displays we used to use, the flyback transformer played an important role, like a producer of high-voltage electricity. Let's talk about how it works:

Manufacturing high voltage

CRT requires high voltage to make the electrons fly fast enough to display images on the fluorescent screen. The flyback transformer is like a booster, converting the low voltage we usually use into the high voltage required for CRT. This voltage is quite high, ranging from over 10000 to 30000 volts, or even higher.

Storage and transmission of energy

When the flyback transformer works, it is like a small energy storage warehouse. As soon as the switch is turned on, it begins to store energy in the magnetic core inside. As soon as the switch is turned off, the magnetic field disappears and the stored energy flows to the secondary winding, becoming high voltage electricity that supplies power to the CRT.

Adjust voltage

The flyback transformer also needs to help adjust the voltage to ensure that the CRT receives just the right voltage, so that the image can be clear and the brightness can be sufficient. In many CRT devices, it is a major player in switch mode power supplies.

Turn the electron beam

In addition to generating high voltage, the flyback transformer also needs to help bend the electron beam. In old-fashioned CRT televisions or monitors, the electron beam has to sweep back and forth on the screen to form an image, and this turning action is driven by the high voltage of the flyback transformer.

Ensure safety

The flyback transformer also needs to act as a "gatekeeper" between high and low voltage to prevent high voltage electricity from running around and causing electric shock or short circuit, ensuring our electrical safety.

How Does A Flyback Transformer Store and Release Energy during Operation

The flyback transformer is like a small energy warehouse, using the magnetic field inside to store and release energy. The whole process is divided into two steps:

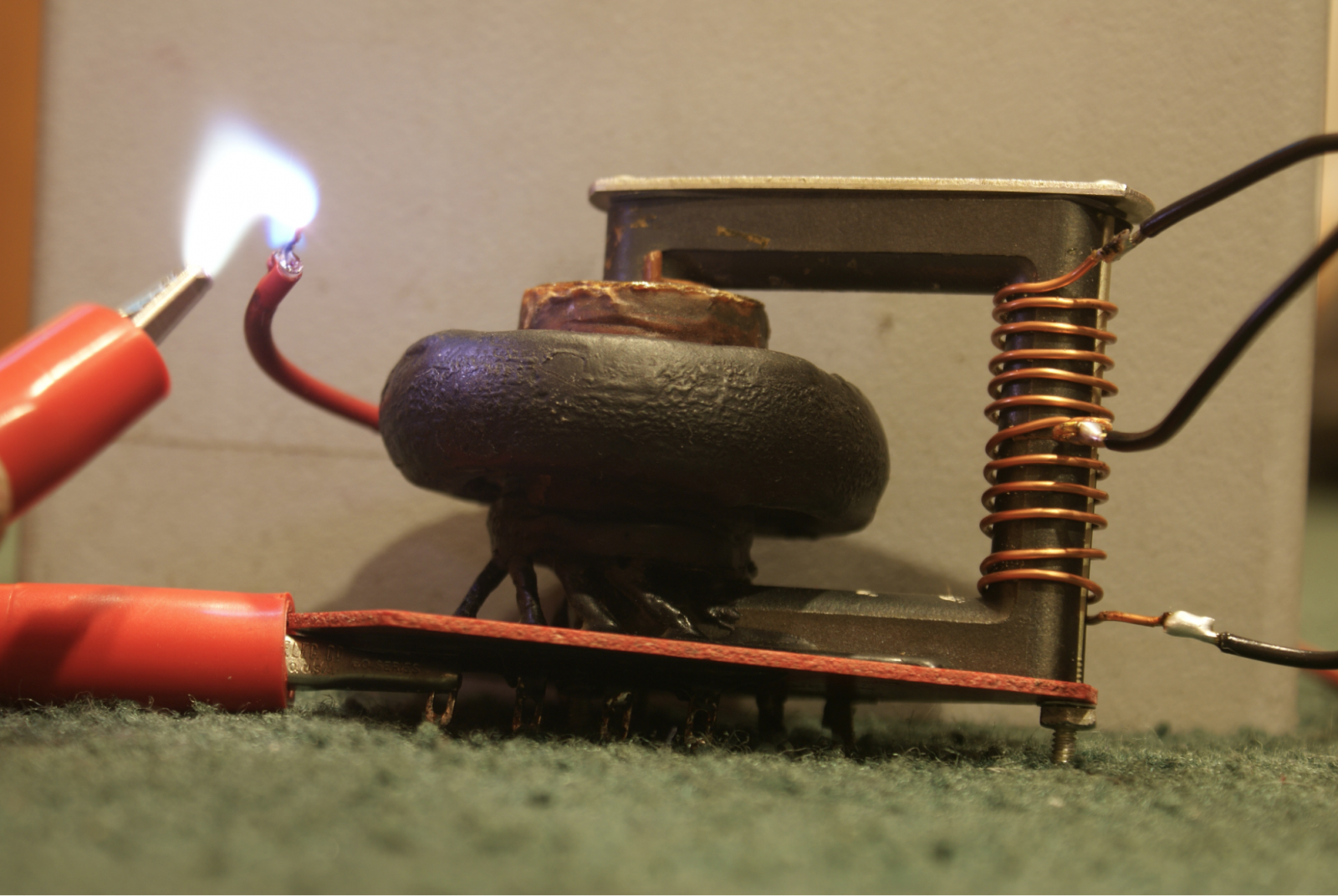

Image Source: Hackaday

Energy storage: When a switch (usually a transistor) is closed, current flows through the primary coil, winding around the transformer core to form a magnetic field. As long as the switch is not turned off, the energy brought by the current will be stored in this magnetic field.

Energy release: As soon as the switch is turned on, the magnetic field is like a deflated ball that disappears with a swoosh. At this point, according to Faraday's law of induction, a voltage will be induced in the secondary coil. The induced voltage is sent to the secondary circuit, rectified, and becomes the output voltage we need.

The Key Design Considerations when Selecting A Flyback Transformer for A Specific Application

Choosing a flyback transformer requires careful consideration of several key points to ensure its usability, high efficiency, and reliability. We need to consider these aspects:

Input and output voltage requirements:

Input voltage: It is necessary to know what input voltage (AC or DC) the transformer needs to use, which will affect the design of the primary coil.

Output voltage: The desired output voltage (AC or DC), whether to boost or buck, must be considered.

Voltage ripple: To ensure stable voltage, it is necessary to find a way to minimize ripple during design, which may require the use of filtering components.

Power level

Output power: The transformer must be able to withstand the required output power, usually expressed in watts (W), which determines the size and current carrying capacity of the coil.

Efficiency: High efficiency results in less energy consumption and heat generation. Efficiency is affected by factors such as iron core material, coil resistance, and switching frequency.

Switching frequency

Working frequency: Flyback transformers have a high working frequency (usually tens to hundreds of kHz), which needs to be matched with application requirements, balancing efficiency and volume.

Core loss: With high frequency, the core loss is large, so it is necessary to choose suitable core materials and designs to reduce losses.

Core material and size

Core type: The material (such as ferrite, iron powder) and shape of the core have a significant impact on its performance, and ferrite is commonly used in high-frequency applications.

Saturation point: The iron core must be able to withstand peak magnetic flux without saturation. When saturated, efficiency decreases and output quality is also poor.

Core loss: By selecting the right material and geometric shape, the core loss will be reduced during operation, especially at high frequencies.

Isolation requirements

Electrical isolation: The flyback transformer must provide electrical isolation between the primary and secondary coils to ensure safety and prevent ground loops. The isolation voltage must meet the application requirements.

Regulation and feedback

Adjustment: The transformer must meet the adjustment requirements of the application, that is, the load must be changed and the output voltage must be stable.

Feedback mechanism: Adjust the output voltage and switch duty cycle using a feedback loop (usually through the secondary coil). The transformer is designed to support this adjustment method.

Current level and output power capability

Current handling: The transformer must be able to withstand the required output current, without overheating or overloading. The wire specifications and coil design affect the current carrying capacity.

Load conditions: Consider whether the application is constant load or variable load, and how the transformer performs under these conditions.

Size and packaging

Physical dimensions: The flyback transformer must be able to fit into the application. Small efficiency is high, but output power may be limited.

Thermal management: Transformer size affects heat dissipation. If necessary, cooling or heat sinks should be added to prevent overheating.

Cost and availability

Cost constraint: Designed to balance performance and cost. High performance transformers may be expensive, depending on the project budget.

Delivery time and availability: Depending on the application timeline, the availability of a specific transformer design may be a factor. Some specialized delivery times may be longer.

Reliability and environmental factors

Temperature range: Ensure that the transformer can operate within the temperature range of the application environment (such as industrial, automotive, consumer electronics).

Durability: Transformers must be sturdy enough to withstand the expected lifespan of the application, while also considering vibration, impact, and environmental conditions such as humidity and dust.

Electromagnetic interference (EMI)

EMI shielding: High frequency transformers may generate EMI and interfere with other electronic devices. Designed to include shielding or other techniques to reduce EMI and comply with regulatory standards such as FCC and CE.

Regulatory compliance

Safety standards: Depending on the application, transformers may have to comply with specific safety standards (such as UL, CE, RoHS), involving isolation, voltage levels, and structure.

Certification: Ensure that transformers comply with relevant industry certifications and quality control standards.

Is Flyback Transformer AC or DC

Image Source: Schott Magnetics

A flyback transformer can operate with both AC and DC inputs, but it is most commonly used in DC applications.

In typical use, the primary winding of a flyback transformer is driven by a pulsed DC signal. This is often provided by a switching transistor (like a MOSFET) in a switched-mode power supply (SMPS), where the transistor rapidly turns on and off. The pulsed DC current through the primary winding generates a changing magnetic field in the transformer core.

The changing magnetic field induces voltage in the secondary winding, which is then rectified to provide a stable DC output. While the transformer can work with AC in certain configurations (like in AC-DC converters), the pulsed DC input is what allows the flyback transformer to efficiently store and release energy in the core.

Final Verdict

Looking ahead, flyback transformers will continue to play a significant role in power supply designs, especially as the demand for compact, efficient, and cost-effective solutions grows in industries like consumer electronics, electric vehicles, and renewable energy. Advancements in materials, design optimization, and integration with modern switching technologies may lead to even higher efficiency, smaller form factors, and better thermal performance, making flyback transformers an essential component in future power electronics.

Disclaimer: The views and opinions expressed by individual authors or forum participants on this website do not represent the views and opinions of Chipsmall, nor do they represent Chipsmall's official policy.

share this blog to: