OUTLINE:

A Beginners Guide: How to Crimp Ring Terminal

325

325Crimping ring terminals is an essential skill for electrical and automotive enthusiasts. This article will provide a brief introduction to ring terminal and why we should crimp it. Finally, we will focus on how to crimp ring terminal.

What is Ring Terminal

A ring terminal is a type of electrical connector commonly used to attach wires to electrical devices and fixtures. It is typically made of metal and shaped as a ring or a circular disk, designed to be easily attached to the wire terminals on electrical devices. By inserting a wire into the ring terminal and compressing it using the appropriate tool, a secure electrical connection is established. This type of connection provides good conductivity and can withstand the transmission of electricity and voltage. Ring terminals are widely used in various applications, including electrical connections for household appliances, industrial equipment, and automobiles.

Why We Should Crimp Ring Terminal

There are several reasons why we should crimp a ring terminal:

1. Secure Connection:

Crimping a ring terminal ensures a secure connection between the wire and the electrical device. The compression of the terminal around the wire creates a strong mechanical bond, reducing the risk of wire displacement or loosening over time.

2. Electrical Conductivity:

Crimping a ring terminal also ensures good electrical conductivity between the wire and the device. The contact area between the wire and the terminal is increased, reducing resistance and heat build-up, which can lead to premature failure of the connection.

3. Safety:

A securely crimped ring terminal reduces the risk of electrical fires or other safety hazards. By ensuring a reliable connection, you reduce the chances of electrical sparks or arcing, which can lead to equipment damage or personal injury.

4. Ease of Installation:

Crimping a ring terminal is a quick and efficient way to make electrical connections. It eliminates the need for time-consuming and error-prone wire splicing or other types of connections, making it ideal for professional and do-it-yourself applications.

5. Durability:

Crimped ring terminals are typically more durable than other types of electrical connections, providing a longer service life for the connection. The compression of the terminal onto the wire helps to protect the connection from environmental factors such as vibration, moisture, and corrosion.

In conclusion, crimping a ring terminal is essential for ensuring a secure, safe, efficient, and durable electrical connection. It provides a reliable means of attaching wires to electrical devices, promoting safety while reducing the risk of equipment failure over time.

How to Crimp Ring Terminal in 5 Steps

Before you can proceed with the new connection, you must select the appropriate ring terminal from the insulated and non-insulated alternatives offered.

Step 1: Select a Ring Terminal

Choosing non-insulated or insulated ring terminals will depend on a number of factors. For economical purposes, non-insulated types are best. There are also non-insulated types that are designed to be used for high temperatures. Insulated types provide protection either in vinyl or in nylon types. Vinyl is more economical, but nylon provides better quality and durability. Heatshrink ring terminals provide the highest protection against damaging elements.

Step 2: Select a Tool for Crimping

Crimping tools are not created equal. Make sure to choose one that is best for the gauge of the ring terminal usually crimped. Make sure to read forums and buying guides in order to choose the right type of crimping tool for the job.

Step 3: Strip the Wire

To strip the wire, make sure to take note of the proper stripping length recommended. This can be done manually by measuring the length of the insulation provided in the ring terminal. Transfer that measured length to the wire. Strip the wire in order to expose the copper wire inside. The stripper can either be provided along with the crimp tool. Depending on the design of the tool, the stripper can either be found on the head or behind the hinge. If the crimp tool does not have a stripper, then use a separate stripper.

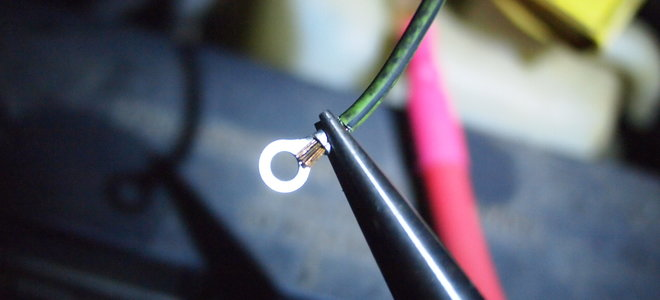

Step 4: Insert the Bare Wire into the Terminal

Insert the stripped wire into the end of the terminal and press it firmly until the wire insulation meets the terminal insulation. Never allow the bare wire to be exposed to avoid problems in the future.

Step 5: Crimp the Terminals

Insert the stripped wire into the end of the terminal and press it firmly until the wire insulation meets the terminal insulation. Never allow the bare wire to be exposed to avoid problems in the future.

Place the end of the terminal into the crimp tool. Make sure that the terminal is placed at the correct rise size and that the casing is placed in the middle of the rise. Gently close the tool to grip the casing. Afterward, squeeze the tool as hard as you can. Check if the crimp is successful by pulling the wire from the terminal lightly. If the wire does not come off, then the crimp is successful.

Ring Terminals VS Spade Terminals

The sole true distinction is that ring terminals have a ring-shaped end, whereas spade terminals have a fork-like, spade-shaped end.

To some extent, Ring terminals can provide superior protection against loosening and disconnection since the end of a ring terminal is completely closed. As a result, even if there are vibrations, it should not come loose from the equipment or system to which it is linked.

The same situation may cause spade terminals to loosen because the end is open.

Final Verdict

While crimping ring terminals may seem like a complex process, with practice you'll get the hang of it. It’s recommended to practice on a few sample wires before attempting it on a real electrical circuit to familiarize yourself with the technique. With proper technique and attention to detail, you can achieve reliable and safe electrical by knowing how to crimp ring terminal.

Disclaimer: The views and opinions expressed by individual authors or forum participants on this website do not represent the views and opinions of Chipsmall, nor do they represent Chipsmall's official policy.

share this blog to: