OUTLINE:

How to Use a Terminal Block

394

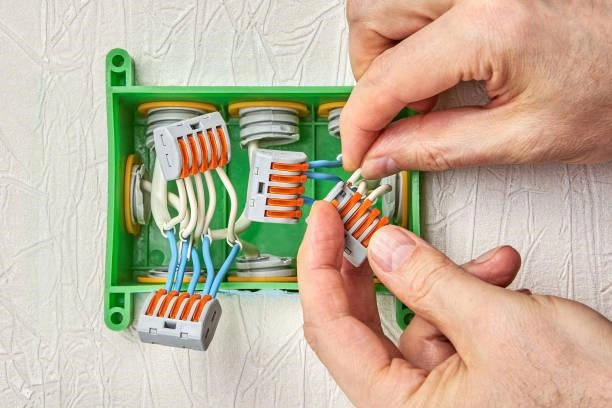

394Because they offer a safe and orderly method of connecting wires, terminal blocks are essential parts of electrical and electronic systems. Knowing how to use a terminal block can speed up your wiring process and improve the security and dependability of your connections, whether you’re working on a straightforward home project or a sophisticated industrial setup. To help you complete your wiring tasks accurately and effectively, we will go over the fundamental procedures and industry best practices for, utilizing terminal blocks in this guide.

Recognizing the various varieties and their uses is one of the first steps toward learning how to operate a terminal block. Several types of terminal blocks, such as barrier strips, screw-ins, and spring clamps, are intended to fulfill a specific wiring requirement. For your project to turn out the best, you must know which type to utilize, which is covered in the previous article < How Do Terminal Blocks Work: A Comprehensive Guide>.

Understanding how to wire a terminal block is another essential skill. An increased system lifespan and decreased risk of electrical failure are two benefits of using proper wiring techniques that guarantee secure connections. From stripping the wires to securing them in place, this guide will take you step-by-step through the wiring of a terminal block.

You will be able to approach your wiring projects with competence and confidence after reading this article, which will give you a firm grasp of how to wire a terminal block and how to use a terminal block as well.

What is a terminal block

The crucial parts of electrical and electronic systems that link and arrange numerous wires are called terminal blocks. They offer a safe and effective way to handle electrical connections, making circuits easy to maintain and stable. It is essential for everyone working with electrical wiring, whether in a home business or industrial setting, to understand what terminal blocks are and how to use a terminal block.

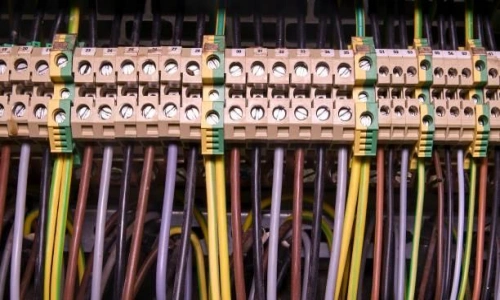

There are several types of terminal blocks, such as barrier strips, screw-ins, and spring clamps, each intended for a particular use in a particular setting. One common option in many wiring projects is screw-in terminal blocks, which are well-liked for their dependability and simplicity of use. When frequent and rapid changes are required, spring clamp terminal blocks provide an easy-to-use tool-free connection method. Barrier strips improve organization and safety by clearly demarcating spaces between connections.

Simplifying wiring is one of the main purposes of terminal blocks. Terminal blocks provide a neat orderly and easily adjustable connection as an alternative to soldering wires together or utilizing other less dependable techniques. This is especially crucial for complex systems where it is necessary to connect and manage numerous wires effectively.

Common applications

As they can offer structured and safe electrical connections, terminal blocks are adaptable parts that are utilized in a wide range of sectors and applications. In electrical and electronic projects, there are many more options available when one knows how to use a terminal block efficiently. Here are a few typical uses for terminal blocks:

- Industrial Control Systems

Terminal blocks are essential for linking and organizing the wiring of automated systems, machinery, and control panels in industrial settings. They make intricate wiring configurations easier to arrange and guarantee safe, trouble-free connections.

- Electrical Distribution

Electrical distribution boards frequently utilize terminal blocks to join incoming and outgoing wires. They help keep electrical panels organized and accessible by offering a reliable and effective means of distributing power among several circuits.

- Automotive Wiring

Terminal blocks are used in the automotive industry to link and control the different electrical systems in cars. They guarantee that the connections are sturdy and resilient enough to endure the challenging circumstances like temperature swings and vibrations that are frequently present in automotive settings.

- Building and Construction

Terminal blocks are utilized for lighting systems, junction boxes, and other electrical installations in both residential and commercial buildings. They offer a tidy and safe way to join wires, which facilitates long-term electrical system maintenance and upgrades.

- Telecommunications

Telecommunications equipment often relies on terminal blocks to manage and organize wiring for communication networks. They ensure that connections are reliable and can be easily modified as network configurations change.

- Renewable Energy Systems

In renewable energy applications, such as solar and wind power systems, terminal blocks are used to connect panels, inverters, batteries, and other components. They play a critical role in ensuring that connections are secure and capable of handling varying power loads.

- Instrumentation and Measurement

To connect sensors, transducers, and other devices instrumentation and measurement equipment, use terminal blocks. Accurate data collection and analysis depend on precise and stable connections which they guarantee.

How to use a terminal block: Step-by-step guide

When connecting multiple wires securely in electrical wiring a terminal block is a necessity. Here is a detailed tutorial on how to use a terminal block:

Step-by-Step Guide to Using a Terminal Block

1. Choose the Right Terminal Block

Based on the application requirements for connection voltage and current rating, choose a terminal block that meets those needs.

2. Prepare Your Wires

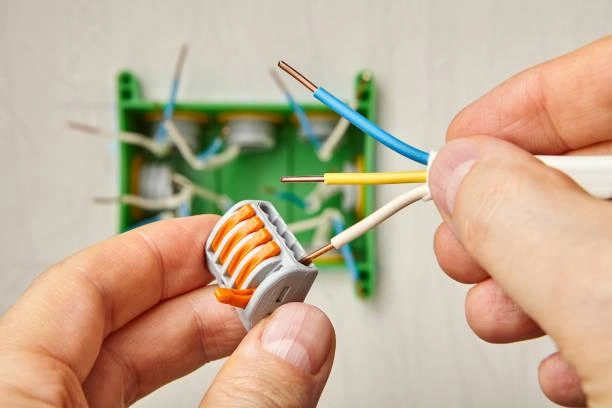

After removing the insulation, cut the wires that you want to attach to the terminal block. The usual procedure to reveal the conductor on each wire end is to remove 8–10 mm (0–0. 34 in) of insulation.

3. Insert the Wires

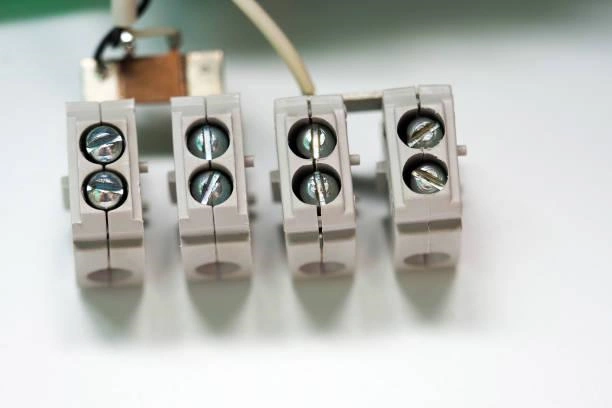

Determine which slots or entry points each wire in the terminal block uses. To secure the wires in place, most terminal blocks feature a screw or clamp mechanism.

Place a wire in the appropriate opening or beneath the clamp mechanism. Make sure there is no insulation caught under the clamp and that the conductor is fully inserted.

4. Secure the wires

To firmly anchor the wires, tighten the screws or clamps. Make sure the screws are securely fastened and that they are in good contact with the conductors by using the proper screwdriver or other tool.

5. Check Connections

Pull each wire gently to make sure it is securely fastened after all the wires have been fastened. Once the wires are securely fastened, they shouldn't move or slip.

6. Label if Necessary

Consider labeling every connection point if the terminal block is going to be a part of an intricate wiring configuration so that it will be simpler to identify during maintenance or troubleshooting.

7. Close the Terminal Block (if applicable)

Certain terminal blocks have lids or covers that must be closed after wiring to shield the connections from outside influences or unintentional contact.

8. Test the Connections

Use a multimeter to check for continuity and make sure the terminal block is free of loose connections or short circuits before supplying power.

Additional Tips

Safety first: To prevent electrical hazards, always work with the terminal block when the power is off.

Appropriate Sizing: Verify that the terminal block has enough room to hold the wire gauge you’re using without packing the terminal too full or too empty.

Routine Maintenance: Check terminal blocks periodically for damage that might impair performance loose connections or corrosion.

These instructions will help you learn how to use a terminal block in a variety of electrical wiring projects. And, understanding how to wire a terminal block ensures reliable connections and safe operation of electrical circuits.

Installation Maintenance tips

To guarantee dependable electrical connections, a terminal block must be installed and kept up. To help you along the way consider the following crucial advice:

Installation Tips

- Select the Proper Terminal Block - Consider features like voltage rating current rating and type of terminal (screw-type spring-clamp etc.) when choosing a terminal block that best suits your application requirements. Reliability and compatibility are thus guaranteed.

- Get your workspace and tools ready - Assemble the required tools, such as wire strip the right screwdrivers and stripped wires that are the right length (usually 0-3/4 inches or 8-10 mm). Make sure the area around you is safe and well-lit.

- Get the Wires Ready - The wire ends that will be connected to the terminal block should have their insulation carefully removed. Make sure there are no loose threads or damage on any of the conductors.

- Put the wires in and fasten them securely - Each wire should be inserted into the appropriate slot or under the terminal block clamp mechanism. Use the proper screwdriver to firmly tighten the screws on screw-type terminal blocks. Make sure the mechanism holding the wires in place for spring-clamp or push-in terminal blocks is holding them firmly.

- Check the Connectivity - Make sure each wire is securely fastened in place by giving it a little tug after you have fastened them all. Intermittent contact and possible failures are avoided with properly secured connections.

Maintenance Tips

- Check for wear and corrosion during routine inspections.

- Maintain Cleanliness - Take out dust and debris regularly.

- Tighten the screws to make sure the connections are solid.

- Check for Continuity - Make sure to use a multimeter.

- Observe Guidelines - Comply with the directions provided by the manufacturer.

How to wire a terminal block

Use these procedures to understand how to wire a terminal block efficiently –

- Choose the Appropriate Terminal Block - A terminal block that satisfies the voltage and current requirements should be selected for your application. Knowing how to use a terminal block correctly requires that you complete this step.

- Get your wires and tools ready - assemble wire strippers and wires that are the right size and have been stripped to reveal about 8 to 10 mm (0 to 3 1/4 inches) of conductor. Connect wires to the terminal block as follows.

- Determine which slots or entry points each wire uses - Make sure no insulation gets tangled in screws or clamps firmly insert each wire.

- Safeguard the Connections - Tighten screws or firmly engage clamps with a screwdriver to guarantee wires are held firmly in position. To wire a terminal block securely, you must complete this step.

- Examine and try the connections - After wiring, ensure each wire is held firmly by giving it a little tug. Verify correct electrical connections and conduct continuity tests with a multimeter.

- Finish the Terminal Block by labeling it - Label connections to make identification easier in the future. To protect connections from the elements, close the terminal block cover if one is available.

By following the above steps on how to wire a terminal block, you can guarantee dependable electrical connections. It also maintains safety and functionality by performing routine maintenance and inspections.

FAQs

Here are some frequently asked questions (FAQs) about using and wiring terminal blocks, incorporating the keywords "how to use a terminal block" and "how to wire a terminal block":

Q: What is the purpose of a terminal block?

Multiple electrical wires can be safely and neatly connected with the help of a terminal block. In a variety of electrical applications, it offers a practical means of distributing power or signals.

Q: How to wire a terminal block?

Follow these steps to wire a terminal block:

• Choose the appropriate terminal block for your needs.

• Prepare your tools and ensure that the wires are stripped so that the conductor is exposed.

• Make sure every wire is positioned underneath the clamp or in the proper slot.

• To secure the wires use firmly locking clamps or tightening screws.

• Test connections with a multimeter to ensure proper continuity.

Q: How can a secure connection be guaranteed in a terminal block?

Make sure all wires are properly stripped and completely inserted into the terminal block, making sure no insulation gets trapped between screws or clamps. To keep the wires in place, tighten screws or firmly clamp them in place.

Q: What kind of upkeep are terminal blocks required for?

Check terminal blocks frequently for indications of rust wear or loose connections. Keep dust and debris away from them. To ensure strong connections, tighten screws regularly. Use a multimeter to check for continuity.

Conclusion

In conclusion, understanding how to use and wire a terminal block is essential for creating reliable electrical connections in various applications. Electrical distribution can be made safe and effective by choosing the appropriate terminal block, setting up wires appropriately, and tightening connections. Over time, optimal performance can be maintained through regular maintenance, which includes testing for continuity and inspecting for wear. Terminal blocks contribute to strong electrical systems in both AC and DC applications when these procedures are followed in addition to safety precautions. Being familiar with these procedures and performing preventative maintenance will increase longevity and dependability guaranteeing smooth operation in a variety of electrical environments.

Disclaimer: The views and opinions expressed by individual authors or forum participants on this website do not represent the views and opinions of Chipsmall, nor do they represent Chipsmall's official policy.

share this blog to: