OUTLINE:

Analysis of Ignition System: Principle, Failure, Diagnosis and Prevention

486

486The engine ignition system is an essential component of the car engine. Its proper operation is directly proportional to the engine's power production, fuel efficiency, and emissions performance. For automotive repair technicians, a thorough understanding and command of the construction and operation of the ignition system is critical to assuring the quality and efficiency of repairs. This article will examine the engine ignition system in depth and discuss its significance in automotive maintenance.

Basic Concepts of Engine Ignition System

The engine ignition system refers to the device that uses electric sparks to ignite the mixture in a gasoline engine (gasoline engine). Its function is to ignite the combustible mixture in the cylinder with electric sparks when the compression is close to the top dead center, so that it burns and performs work. The working process of the engine ignition system is actually the process of spark generation and discharge. In most gasoline engines, the mixture of fuel and air in the cylinder is ignited by electric sparks near the end of compression. This ignition method is called spark ignition.

Construction of Ignition System

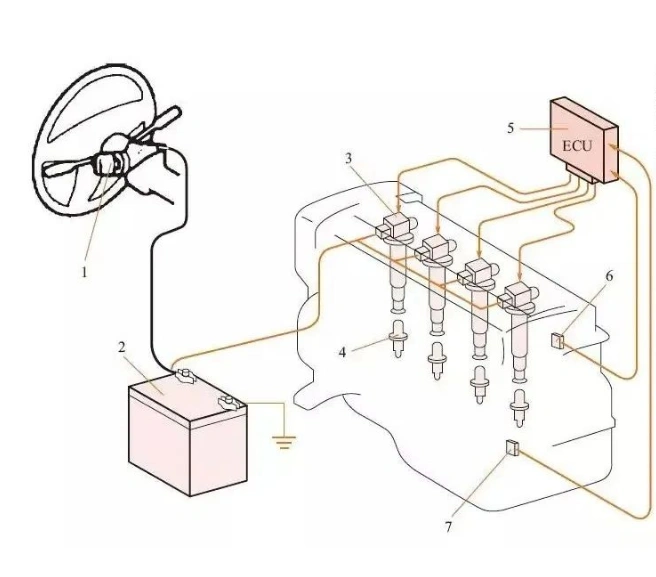

- 1—Ignition switch

- 2—Battery

- 3—Ignition coil with igniter

- 4—Spark plug

- 5—Engine ECU

- 6—Camshaft position sensor

- 7—Crankshaft position sensor

The ignition system consists of a power source (battery), sensors, ECU, igniter, ignition coil, spark plug, etc. The ignition system generates sparks under high voltage and ignites the compressed mixture in the cylinder at the best timing. Based on the signals received from various sensors, the engine ECU (electronic control unit) implements control to achieve the best ignition timing.

Function of automobile ignition system

- The ignition system converts the low voltage of the power supply into high voltage, and then sends it to each cylinder in turn according to the engine ignition sequence to ignite the compressed mixture;

- It can adapt to changes in engine working conditions and usage conditions, automatically adjust the ignition timing, and achieve reliable and accurate ignition;

- Manually calibrate the ignition timing when changing fuel or installing distributors.

Working Principle of Engine Ignition System

The working principle of engine ignition system is that when the engine is working, the crankshaft drives the rotor of the distributor (or ignition coil) to rotate. When the bump on the distributor shaft or the contact gap on the ignition coil approaches the protruding part of the pulse signal generator (inductor) until it contacts, the secondary induced current generated in the inductor flows from the ground through the movable contact arm to the distributor cap side electrode, the distributor head, the side electrode, the spark plug oil inlet bolt, the center electrode, and then flows to the ground to form a loop. In this way, the induced current passes through the spark plug gap, causing the spark plug to generate an electric spark to ignite the combustible mixture. The components of the ignition system are divided into traditional ignition system and electronic ignition system. The traditional ignition system is mainly composed of power supply (battery and generator), ignition switch, ignition coil, capacitor, breaker, distributor, spark plug, high-voltage wire and additional resistor. The electronic ignition system is completely different from the traditional ignition system. It cancels the breaker and uses transistors as switching elements, so it is also called transistor ignition system.

Common faults diagnosis of engine ignition system

When the car engine cannot start and it is confirmed that the starting system is working properly, or when the normally working engine suddenly stops working and there is no high voltage connected to the spark plug, it may be caused by an abnormality in the ignition system. The following are two methods to confirm whether the car ignition system is faulty when the engine cannot start.

(1) Central high-voltage wire sparking method

This judgment method is applicable to ignition systems with distributors. The specific method is as follows:

Pull out the central high-voltage wire from the distributor cap and keep it 5 to 9 mm away from the cylinder body. Then start the engine and observe the sparking of the wire end. If there is no sparking, it means that the ignition system is faulty. Check the sensor, electronic igniter, and ignition coil, and repair and adjust them if necessary.

(2) Spark plug grounding method

This judgment method is applicable to ignition systems without distributors. The specific steps are: remove the ignition coil → separate the injector connector (to prevent fuel injection during inspection) → use the spark plug sleeve to remove the spark plug → install the spark plug on the ignition coil → ground the spark plug to the engine.

Common ignition system faults mainly include: ignition timing misalignment, ignition coil failure, spark plug failure, etc. When the ignition system fails, we can make a preliminary diagnosis by observing the operation of the engine, listening to the engine sound, checking the ignition coil and spark plug, etc.

Repair and maintenance of the engine ignition system

Regular inspection

Clean and inspect the exterior of the ignition system regularly to ensure that the ignition coil housing is free of oil, dust, damage, loose terminals, etc., and replace aging or damaged ignition coils in time.

Keep the ignition coil dry

Prevent the ignition coil from being heated or damp, and maintain its good insulation performance. If there are water stains on the ignition coil, wipe it dry with a cloth in time.

Timely update

Even if there is no fault in the ignition system, it is generally recommended that the vehicle be checked after driving about 20,000 kilometers; after driving 60,000 kilometers, the high-voltage ignition wire should be replaced. If the engine is unstable and cannot be started before checking, it may have caused irreversible wear to the engine.

Can a car be repaired without knowing the ignition system

For a mechanic who does not know the engine ignition system, it will indeed increase the difficulty of repairing the car to a certain extent. However, this does not mean that the car cannot be repaired. With the development of science and technology, modern automobile repair tools and technologies have become more and more advanced, and many faults can be quickly located through professional diagnostic equipment. At the same time, rich maintenance experience and continuous learning are also the key for mechanics to overcome difficulties. Of course, in order to better solve the problem of the engine ignition system, mechanics should still work hard to learn and master relevant knowledge. This can not only improve maintenance efficiency, but also reduce misjudgment and unnecessary losses. In addition, communicating with peers, participating in training courses, reading professional books, etc. are all effective ways to improve their own skills.

Disclaimer: The views and opinions expressed by individual authors or forum participants on this website do not represent the views and opinions of Chipsmall, nor do they represent Chipsmall's official policy.

share this blog to: