OUTLINE:

8 Types Integrated Circuit Testing You Should Know

1473

1473IC testing refers to the process of testing integrated circuits (ICs) to ensure their functionality, performance, and reliability. It is a crucial step in the semiconductor manufacturing process to identify and eliminate defective components. In this passage, we are going to explain the 8 types of integrated circuit testing and the reasons that cause integrate circuit to break down.

What are the 8 Types of Integrated Circuit Testing

There are several types of IC testing, each serving a specific purpose. Here are some common types:

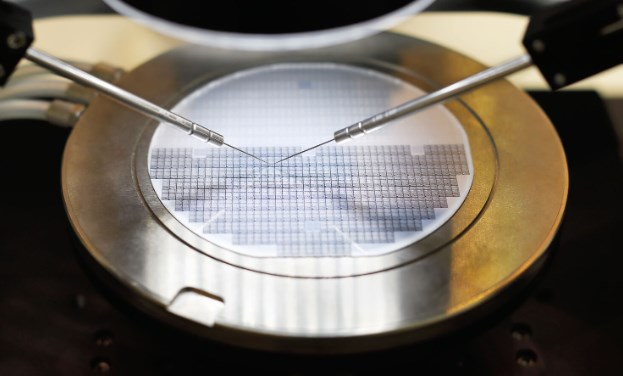

1. Wafer Testing

Wafer tesing is conducted at the wafer level before individual ICs are separated and it identifies defective chips early in the manufacturing process. Usually, simple functional tests are performed to detect gross defects.

2. Final Test (Post-Packaging Testing)

In addition to basic electrical tests, functional tests are conducted to ensure that the circuits on the wafer perform their intended functions. Various input signals are applied to the ICs, and the corresponding output responses are measured. Functional testing at the wafer level helps identify defects that may not be evident through electrical testing alone.

3. Reliability Testing

Reliability testing assess the long-term reliability of the IC by subjecting it to stress tests, such as accelerated aging and thermal cycling. This helps identify potential issues that may arise over time.

4. Parametric Testing

Parametric testing measures specific electrical characteristics of the IC, such as voltage, current, and resistance, to ensure they fall within the specified range. It helps identify variations in performance that may affect functionality.

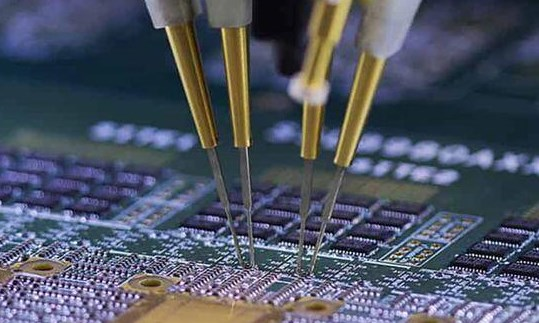

5. In-Circuit Testing (ICT)

In-Circuit Testing Verifies the functionality of the IC while it is connected to the larger circuit board or system. This is commonly used for testing assembled electronic products.

6. Boundary Scan Testing

Boundary Scan Testing uses the Joint Test Action Group (JTAG) standard to test the interconnections and logic on an IC. It is particularly useful for detecting faults in digital designs.

7. Memory Testing

Memory Testing focuses specifically on the memory components of the IC, ensuring that data storage and retrieval functions operate correctly.

8. Yield Analysis

Yield Analysis examines the percentage of good dies obtained from a wafer to identify and address manufacturing issues affecting the overall production yield.

These testing methods are typically employed in combination to ensure comprehensive quality control throughout the integrated circuit manufacturing process. The goal is to identify and eliminate defective devices and ensure that the final products meet the specified performance and reliability standards.

What Causes Integrated Circuit to Break Down

Integrated circuits (ICs) can experience breakdowns or failures due to various factors, occurring during manufacturing, operation, or as a result of external influences. Here are common internal and external causes of integrated circuit breakdown:

1. Internal Causes

Manufacturing Defects

Process Variations: Inconsistencies or variations in the semiconductor manufacturing process can result in defects, such as impurities, irregularities, or contamination, impacting the IC's performance.

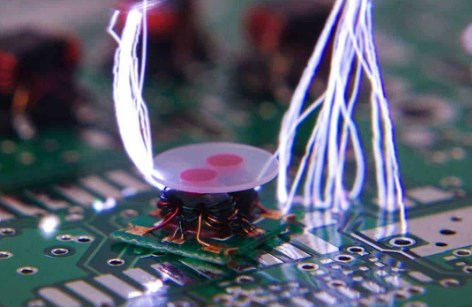

Electrostatic Discharge (ESD)

ESD Events: Sudden discharges of static electricity during handling or manufacturing processes can cause immediate or latent damage to IC components.

Mechanical Stress

Physical Damage: Mechanical stress from bending, flexing, or mechanical shock during handling, installation, or operation can lead to physical damage or microcracks in the IC.

Software Bugs

Firmware or Software Issues: Errors in the firmware or software controlling the IC may lead to incorrect operation, potentially causing damage to the device.

Design Flaws

Poor Design: Inadequate design practices, such as insufficient margin for variations, inadequate testing, or improper consideration of operating conditions, can contribute to failures.

Manufacturing Process Changes

Changes in Manufacturing Process: Alterations to the manufacturing process without proper validation may introduce new failure mechanisms or degrade IC reliability.

2. External Causes

Thermal Stress

Overheating: Elevated temperatures, whether due to high ambient temperatures, excessive power dissipation, or inadequate heat dissipation, can lead to thermal stress, affecting IC reliability.

Electrical Stress

Overvoltage: Applying voltages beyond the specified limits can lead to breakdown of insulating layers and permanent damage to the IC.

Overcurrent: Excessive current can cause overheating, damaging conductive paths or semiconductor materials.

Aging and Wear

Metal Migration: Over time, metal atoms in conductive paths may migrate due to the flow of current, leading to short circuits.

Material Degradation: Materials used in ICs can degrade over time, affecting performance and reliability.

Radiation

Ionizing Radiation: Exposure to ionizing radiation, such as cosmic rays or radiation in space environments, can cause errors and disruptions in IC functionality.

Humidity and Contamination

Moisture and contaminants can cause corrosion of metal contacts or other components, leading to degradation over time.

It's essential for manufacturers to implement robust testing procedures, quality control measures, and reliability testing to minimize the risk of IC breakdowns. Additionally, users should operate ICs within specified operating conditions and handle them with care to avoid mechanical and electrostatic damage. Ongoing research and development efforts continue to address these challenges to improve the reliability and durability of integrated circuits.

Final Verdict

IC testing is a crucial step in the semiconductor manufacturing process. This passage explains the eight types of integrated circuit (IC) testing and the possible causes behind the shut-down of integrated circuits. Hopefully, it will provide you with some insight into integrated circuit testing.

Disclaimer: The views and opinions expressed by individual authors or forum participants on this website do not represent the views and opinions of Chipsmall, nor do they represent Chipsmall's official policy.

share this blog to: