OUTLINE:

Exploring the Feature and Applications of Leadless Chip Carriers

152

152In modern electronics, everyone pursues the smaller the better and the higher the efficiency, the better. Some small parts are actually particularly important, but they are often overlooked.

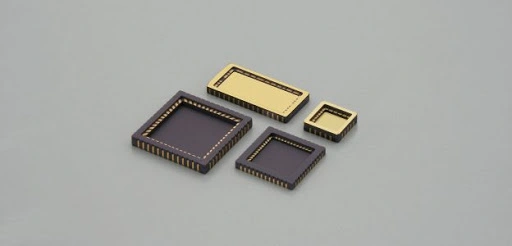

Image Source: Evergreen Semiconductor Materials

For example, the Leadless Chip Carrier (LCC) is a compact, flexible, and sturdy device that can boost the morale of many high-tech products. Nowadays, various industries are striving for innovation, and understanding what LCC is for and where it can be used has become particularly crucial.

Pre-view: What Is A Leadless Chip Carrier

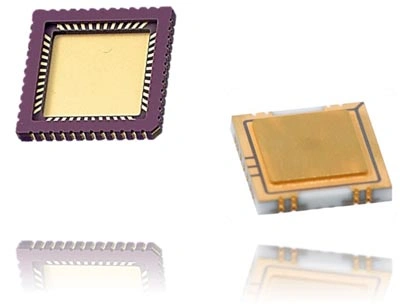

Image Source:Kyocera

A Leadless Chip Carrier (LCC) is a small but powerful part that holds integrated circuits. What makes it different from the usual chip packages is that it doesn’t have leads sticking out. Instead, it uses flat metal pads on the sides or bottom for connections. This makes LCCs more compact, durable, and perfect for squeezing into tight spots. You’ll find them in all kinds of tech that needs to be fast and reliable, like smartphones, medical devices, and even aerospace equipment. It’s a great example of how the smallest components can make a big impact!

Features & Applications of Leadless Chip Carriers

Leadless Chip Carriers (LCCs) come with some pretty awesome features that make them perfect for modern tech:

-

Compact Design: Since they don’t have leads sticking out, LCCs take up less space—great for small devices.

-

Super Tough: With no leads to bend or break, LCCs are more durable and can handle rough conditions.

-

Keeps Cool: The flat metal pads help cool things down, so they don’t overheat.

-

Easy to Install: They’re made for surface-mounting, meaning they’re quick and easy to place on circuit boards.

-

Great Performance: LCCs reduce interference and improve signal quality, making them perfect for fast devices.

Applications

LCCs are used in all sorts of devices where space, performance, and reliability are key:

-

Consumer Electronics: You’ll find them in smartphones, tablets, and wearables, where compact and reliable tech is a must.

-

Car Electronics: LCCs are in car systems like navigation and safety features, where durability and dependability are critical.

-

Medical Devices: They’re used in portable medical gadgets, where being small and reliable is super important.

-

Aerospace & Defense: From satellites to military tech, LCCs perform in the most extreme conditions.

-

Telecom Equipment: In routers and base stations, LCCs help keep signals fast and stable.

What Is the Difference between PLCC and LCC

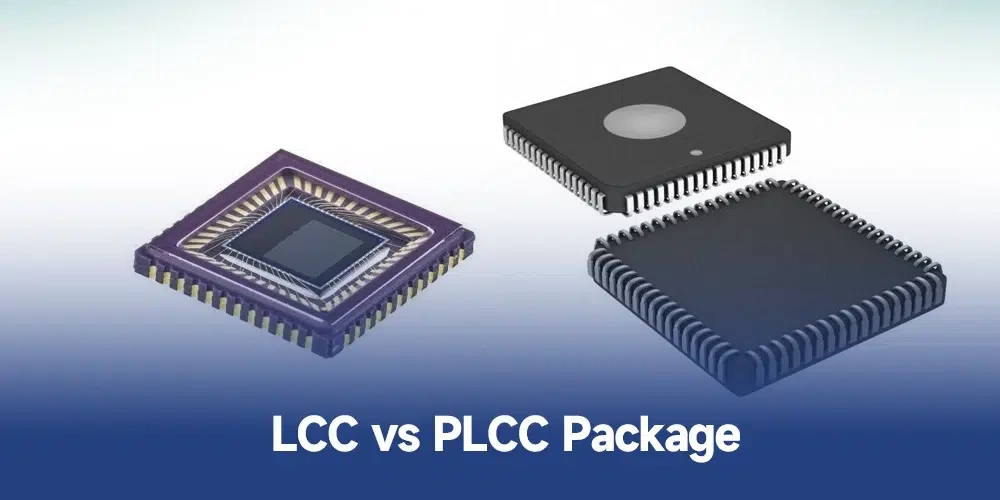

Image Source:IBE

Both PLCC (Plastic Leaded Chip Carrier) and LCC (Leadless Chip Carrier) are types of chip packaging used in electronics, but they’re a little different in how they’re designed and used:

Leads

PLCC has leads (little metal legs) that stick out from the sides of the chip, making it easier to attach to a circuit board with either through-hole or surface-mount methods.

LCC doesn’t have any leads sticking out. Instead, it has flat metal pads on the bottom or sides that connect to the circuit board using surface-mount technology (SMT).

Size and Shape

PLCCs are usually bigger and bulkier because of those leads, so they take up more space.

LCCs are much smaller and have a lower profile, making them perfect for space-saving designs in modern electronics.

How They’re Mounted

PLCCs can be mounted by having the leads go through holes in the circuit board (through-hole) or placed on the surface (SMT) in smaller sizes.

LCCs are mainly mounted directly onto the surface of the board using SMT.

Durability and Reliability

PLCCs are a bit more vulnerable to damage because of the exposed leads, but they’re easy to work with during assembly.

LCCs, with no leads, are more durable and less likely to get damaged, which makes them great for high-performance and compact devices.

The Components of A Leadless Chip Carrier

A Leadless Chip Carrier (LCC) might look simple, but it has some important parts that make it work well in modern electronics:

-

Package Body:

This is the main part of the LCC, usually made from plastic or ceramic. It holds everything together and protects the chip inside. -

Flat Metal Pads:

Instead of the usual leads, LCCs have flat metal pads on the bottom or sides. These pads connect directly to the circuit board using surface-mount technology (SMT), making it super compact. -

Die Attach:

Inside the package is the die (the actual chip). It’s glued or soldered to the bottom of the package to keep it in place. -

Wire Bonds:

Tiny wires connect the chip (die) to the metal pads, letting electrical signals flow between the chip and the circuit board. These wires are usually made of gold or aluminum to ensure good conductivity. -

Lead Frame (optional):

In some LCC designs, there might be a lead frame to help support the die and manage heat, but not all LCCs have this. -

Underfill or Encapsulation:

Some LCCs have an underfill material around the chip, which helps protect it from stress and improves heat dissipation. This is especially useful for high-performance applications.

What Factors to Consider While Choosing A Leadless Chip Carrier

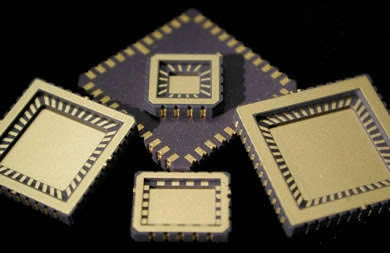

Image Source:Symtezmicro

When you’re picking a Leadless Chip Carrier (LCC) for your project, here are a few things to keep in mind to make sure it’s the right choice:

First, size matters. You need to make sure the LCC fits the space available on your circuit board. They come in different sizes, so you’ll want one that matches your device layout.

Then, check its electrical performance. Make sure the LCC can handle the electrical needs of your project. If you’re working on something high-speed, you’ll need one that keeps signals clean and interference-free.

Heat management is another big factor. Some LCCs are designed to handle heat better, with features like bigger surfaces or built-in heat sinks. This is important if your device will be using a lot of power or generating heat.

Next, think about durability. If your device will be exposed to things like vibrations or temperature changes, you’ll need an LCC that can withstand that. Look for one that’s built to last.

Final Verdict

Leadless Chip Carriers (LCCs) are a crucial but often overlooked component in modern electronics. Their compact size, durability, and efficient performance make them ideal for a wide range of applications, from smartphones to aerospace. By eliminating leads, LCCs save space, enhance reliability, and support faster, high-performance devices. As technology continues to evolve, LCCs will remain a key player in the push for smaller, more efficient electronics.

Disclaimer: The views and opinions expressed by individual authors or forum participants on this website do not represent the views and opinions of Chipsmall, nor do they represent Chipsmall's official policy.

share this blog to: