OUTLINE:

MPT vs. Mixed Component Mounting Technology

173

173In the fast-evolving world of electronics manufacturing, staying ahead of the curve is essential. Two prominent technologies that have significantly contributed to this sector's advancement are MPT (Microelectronic Packaging Technology) and Mixed Component Mounting Technology. These two approaches cater to different aspects of electronic assembly and bring unique advantages to the table.

MPT (Microelectronic Packaging Technology)

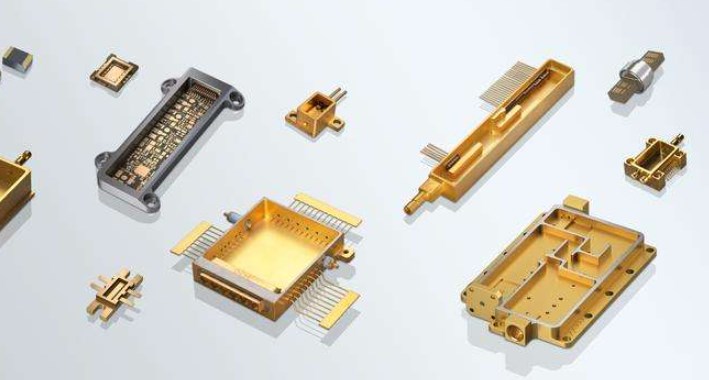

MPT, also known as Microelectronic Packaging Technology, is a specialized branch of electronics packaging that focuses on miniaturization and integration. It is primarily used in industries where size and performance are critical factors, such as aerospace, medical devices, and telecommunications.

Miniaturization: MPT excels in miniaturizing electronic components and circuits, allowing for the development of smaller and lighter devices without compromising performance. This is achieved through techniques like chip-on-board (COB) and chip-on-flex (COF) packaging, where semiconductor chips are directly bonded to substrates.

Integration: MPT emphasizes the integration of multiple functions into a single package. This is achieved by stacking or embedding various components within the same package, reducing the overall footprint of the device. For instance, MEMS (Micro-Electro-Mechanical Systems) sensors can be integrated with semiconductor chips to create compact, multifunctional devices.

Reliability: MPT places a strong emphasis on reliability and durability, as many applications in this field require long-term, uninterrupted operation. Advanced sealing and encapsulation techniques protect sensitive components from environmental factors like moisture, dust, and temperature fluctuations.

Mixed Component Mounting Technology

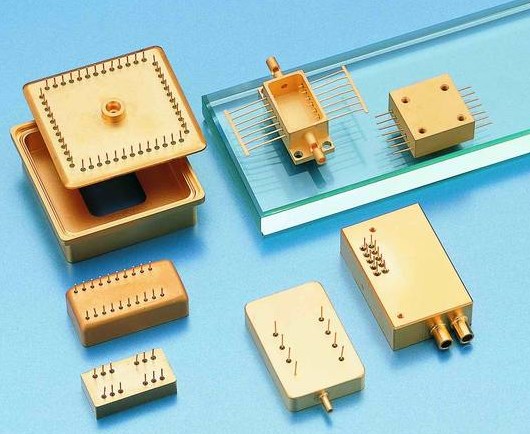

Mixed Component Mounting Technology, on the other hand, is a more versatile approach used in various electronic manufacturing processes. It involves the assembly of electronic components of different sizes, shapes, and technologies onto a common substrate or PCB (Printed Circuit Board).

Versatility: Mixed Component Mounting Technology is highly versatile, accommodating various component types such as surface-mount devices (SMDs), through-hole components, and even advanced packages like ball grid arrays (BGAs). This flexibility is essential for manufacturing a wide range of electronic products.

Cost-Effectiveness: This technology is often favored in high-volume production due to its cost-effectiveness. It allows manufacturers to use a mix of components, optimizing costs while maintaining performance levels. For instance, low-cost through-hole components can be combined with high-performance SMDs.

Repairability: Mixed Component Mounting Technology offers advantages in terms of ease of repair and maintenance. Through-hole components, which are commonly used in this approach, are easily replaceable, making it more convenient to fix and upgrade electronics when needed.

Key Differences

Application Focus: MPT is specialized for applications where miniaturization, integration, and high reliability are paramount, while Mixed Component Mounting Technology is a more general approach used in a wide range of electronic products.

Component Types: MPT predominantly utilizes advanced packaging techniques for semiconductor devices, while Mixed Component Mounting Technology incorporates various component types, including both traditional and advanced technologies.

Cost vs. Performance: MPT prioritizes performance and reliability, which may come at a higher cost, whereas Mixed Component Mounting Technology balances cost-effectiveness and performance, making it suitable for mass production.

In the dynamic field of electronics manufacturing, both MPT and Mixed Component Mounting Technology play vital roles. While MPT excels in applications requiring miniaturization and high integration with a focus on performance and reliability, Mixed Component Mounting Technology offers versatility and cost-effectiveness for a broader range of products. The choice between these technologies depends on the specific requirements of the project, emphasizing the need for manufacturers to stay informed and adaptable in an ever-evolving industry. By understanding the differences and advantages of each approach, electronics manufacturers can make informed decisions that drive innovation and meet the demands of their target markets.

Disclaimer: The views and opinions expressed by individual authors or forum participants on this website do not represent the views and opinions of Chipsmall, nor do they represent Chipsmall's official policy.

share this blog to: