OUTLINE:

Where to Find the Best PLC Controllers for Sale

430

430People engaged in power operations know that industrial production and technological development are inseparable from PLC automation control. In actual production applications, PLC greatly saves the cost of industrial control and strengthens the centralized management and automatic control of equipment.

What is a PLC controller

Programmable logic controllers (PLCs) are solid-state electrical devices that may regulate the functioning of a machine or process. Logic functions are written into PLC memory using programming software. They are intended to monitor data from sources such as pressure sensors, temperature sensors, limit switches, and pilot devices.

A PLC is essentially the brain of an automated operation.

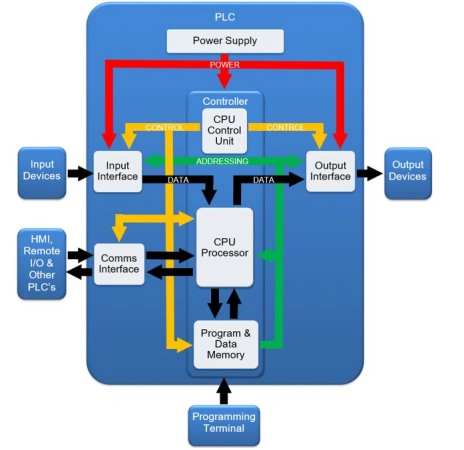

Basic unit of PLC controllers

(1) CPU: the core component of PLC, which directs PLC to perform various tasks. Such as receiving user programs and data, diagnosis, execution of programs, etc.

(2) Memory: storage system and user programs and data.

(3) I/O interface: the connection component between PLC and the controlled object in the industrial production site, used to receive signals from the controlled equipment and output the execution results of the program.

(4) Communication interface: information is exchanged with other devices such as monitors and printers through the communication interface.

(5) Power supply

Image Source: Ladder logic world

Types of PLC characteristics

(1) Integrated type: The CPU, power supply, and I/O components are all concentrated in one chassis. The structure is compact and the price is low. Generally, small PLCs adopt this structure;

(2) Modular type: The various parts of the PLC are divided into several separate modules. Different modules can be selected according to needs to form a system. It has the characteristics of flexible configuration, convenient expansion and maintenance. Generally, medium and large PLCs adopt this structure. Modular PLC consists of a frame or baseboard and various modules. The modules are installed on the sockets of the frame or baseboard.

(3) Stacked type: Combining the characteristics of integrated type and modular type, the CPU, power supply, I/O interface, etc. of the stacked PLC are also independent modules, but they are connected by cables, making the system not only flexible in configuration but also compact in size.

PLC control system VS relay control system

(1) Control method: PLC uses program to realize control, which is easy to change or increase control requirements, and PLC has unlimited contacts;

(2) Working mode: PLC uses serial working mode to improve the anti-interference ability of the system;

(3) Control speed: PLC contacts are actually triggers, and the execution time of instructions is in microseconds;

(4) Timing and counting: PLC uses semiconductor integrated circuits as timers, and the clock pulse is provided by crystal oscillators, with high delay accuracy and wide range. PLC has counting function that relay system does not have;

(5) Reliability and maintainability: PLC uses microelectronic technology, with high reliability, and its self-check function can detect problems in time.

How to choose a PLC logic controller

(1) Model selection: Consider the structural form, installation method, functional requirements, response speed, reliability requirements, model uniformity, etc.

(2) Capacity selection: Consider the number of I/O points and user storage capacity;

(3) I/O module selection: Including the selection of switch and analog I/O modules, as well as the selection of special function modules;

(4) Selection of other equipment such as power modules and programmers.

Top 3 PLC controllers for sale

These leading PLC wholesalers generally provide a wide range of PLC models, accessories, programming software, technical support, and value-added services to fulfill the demands of industrial automation clients.

Siemens: A prominent global provider of industrial automation equipment, including their Simatic PLC line. Siemens has an extensive distribution network for their PLC products. Siemens's PLC products include LOGO, S7-200, S7-1200, S7-300, S7-400, S7-1500, etc.

S7 series PLC products can be divided into micro PLC (such as S7-200), PLC with small-scale performance requirements (such as S7-300) and PLC with medium and high performance requirements (such as S7-400). Siemens S7 series PLC is small in size, fast, standardized, has network communication capabilities, stronger functions and high reliability.

Schneider Electric: A major player in the industrial automation market, offering their Modicon PLC series and other automation solutions through their distribution channels.

Schneider PLC programming software is the core product of Schneider Electric Automation. It is a new generation of software and hardware automation platform.

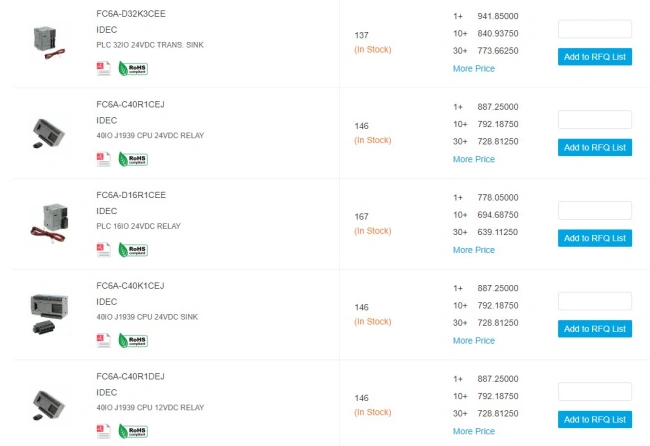

Chipsmall: Chipsmall Limited consists of a professional team with an average of over 20 years of expertise in the distribution of electronic components. With the principle of "Quality Parts, Customer Priority, Honest Operation and Considerate Service", our business mainly focuses on the distribution of electronic components.

With over 1500 results plc controllers for sale, support capabilities of each distributor to determine the best fit for your specific PLC requirements.

FAQs

What is the scan circle of PLC?

The scanning process of PLC includes five stages: internal processing, communication service, input processing, program execution, and output processing. The time required for scanning these five stages once is called the scan cycle.

The scan cycle is related to the CPU running speed, PLC hardware configuration, and the length of the user program.

How to improve I/O response speed?

Because PLC adopts a cyclic scanning working mode of centralized sampling and centralized output, the state of the input terminal can only be read in the input sampling stage of each scanning cycle, and the execution result of the program is only sent out in the output refresh stage; secondly, the input and output delay of PLC, the length of user program, etc. can all cause output response lag.

To improve I/O input sampling, output refresh, or direct input sampling, output refresh, interrupt input and output, and intelligent I/O interface, etc.

In addition to CPU, memory and communication interface, what other interfaces are directly related to the industrial site?

(1) Input interface: Receive the signal of the controlled device and drive the internal circuit to connect or disconnect through the optocoupler and input circuit.

(2) Output interface: The execution result of the program is output through the optocoupler and output components (relays, thyristors, transistors) of the output interface to control the connection or disconnection of the external load.

Final Verdict

After reading this guide, you can learn more about programmable logic controllers. These recommended PLC distributors typically offer a variety of PLC controllers for sale, including accessories, programming software, technical support, and value-added services to meet the needs of industrial automation customers.

Disclaimer: The views and opinions expressed by individual authors or forum participants on this website do not represent the views and opinions of Chipsmall, nor do they represent Chipsmall's official policy.

share this blog to: