OUTLINE:

What is a PLC Module: All You Want to Know

786

786In such a developing society, automated machinery is used to accomplish many of our most vital industrial activities, such as generating electricity and producing products. Automation technology has enabled us to achieve unprecedented levels of production and creativity. Companies on the cutting edge use this automated machinery to supplement human labor and manufacturing procedures, resulting in improved control and continuous output.

Without a fundamental breakthrough known as the programmable logic controller, it is hard to imagine how high the level of automation would be.

What is a programmable logic controller module, and how do they help us operate these advanced processes that our modern world needs? What are the real-life examples of PLCs? This blog will answer your question.

What is a PLC module

Programmable logic controllers (PLCs) are solid-state electronic devices that can control the operation of a machine or process. Logic functions are programmed into PLCs’memory by programming software. They are designed to monitor inputs from sources such as pressure sensors, temperature sensors, limit switches, and pilot devices.

Shortly, a PLC is the brain of an automated process.

A PLC module is a single component of a PLC system. It can provide additional functions for the PLC. Each PLC module can perform a specific function, such as input/output management, communication, or power supply. Multiple PLC modules collaborate to make a comprehensive PLC system.

All of the modules are installed and internally connected with one another within a rack or chassis, which is known as a modular PLC.

How does a PLC operate

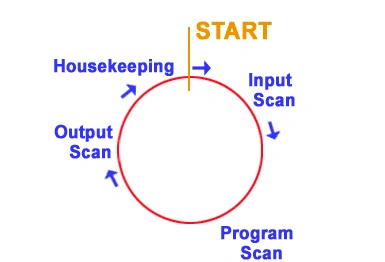

There are four basic processes in the operation of all PLCs: input scan, program scan, output scan, and housekeeping. These stages are repeated in a loop.

1. Input Scan : Detects the status of all input devices linked to the PLC.

2. Program Scan: Executes user-created program logic.

3. Output Scan: Activates or deactivates all output devices attached to the PLC.

4. Housekeeping: This stage involves communicating with programming terminals and performing internal diagnostics.

There are five standard PLC programming languages. The most commonly used language is Ladder Logic, but it is also possible to use Function Block Diagrams, Sequential Function Charts, Structured Text, or Instruction Lists to achieve the same functionality.

Advantages of PLC module

Scalability: The flexibility to add modules repeatedly offers increased scalability for both our PLC control system and the business using the controller. As more modules are added to a single programmable logic controller, the processes become more centralized.

The corporation would be able to expand their assembly lines, for example, by adding more identical output devices that carry out similar functions and can be controlled by the same controller, thanks to the design of the modular PLC.

Easy to troubleshoot: Compared to fixed I/O, fault detection is much simpler with the modular PLC because each function is divided by a separate module.

For example, all of the outputs do not work and the PLC does not receive input from the input devices, it may be that the I/O module is the problem.

Because each component of a PLC module may be addressed independently of the entire PLC system, troubleshooting a PLC module is significantly more convenient.

Less downtime: More time would be needed for the Fixed PLC system to function again because troubleshooting the PLC system would be more challenging.

Troubleshooting will take less time with the modules than with the Fixed I/O because they have independent systems. When something goes wrong, you can definitely use a backup set of modules to replace a broken module right away.

Rich combinations: By allowing you to combine several modules in any way to meet a system objective, this significantly increases the capabilities of the Modular PLC.

In essence, the modular PLC gives you additional customization choices. You can even build a more intricate device system that is capable of tasks you never would have thought a PLC could handle.

More memory: Modular PLCs can have memory expansions for increased storage capacity, just as our own desktop computers.

Types of PLC modules

Different PLC brands may create and produce different kinds of PLC hardware modules for different functions. Here are some examples:

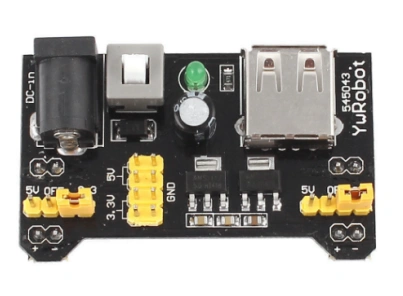

Module for power supply (PS)

A separate module as well as the PLC system's CPU are supplied with the proper voltage by the power supply module.

The PLC power supply transforms line voltage of 100–240 VAC into a lower DC voltage, often 24 VDC, so that the PLC system can function primarily with 24 V DC voltage. Various programmable logic controllers and applications can require varying sizes and ratings for PLC power supplies.

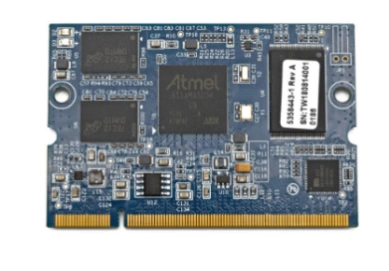

Central processing unit (CPU)

The CPU handles all arithmetic and logical operations. It carries out the commands in accordance with the user's stored program.

The CPU's processor performs calculation tasks like as memory management, input status monitoring, and output activation in response to logical user commands.

Programs and data from the many devices linked to the PLC are stored in the Memory of the CPU.

Interface module (IM)

When there isn't enough space in the main rack for additional input-output modules, you can utilize the interface module instead. It is used for the rack to rack communication in multi-tier configuration in modular PLC system. The interface module connects the other racks to the main rack.

Single module (SM)

The signal module exchanges data information with the input and output modules.

Input signal modules are used to link digital or analog field inputs to a PLC.

Output signal modules are used to connect digital or analog field outputs from the PLC.

These digital or analog I/O signals can be accessed using a signal module.

Communication processor (CP)

The communication processor is an optional element. It can be used to add an extra communication port for communication protocols.

It is used for network communication between several processors or PLCs. Furthermore, CP communicates data with PLC, SCADA, HMI, and other systems.

Real life example of PLC

In such a heavily technologically reliant society, PLC systems are found everywhere. They are so seamlessly and invisibly immersed in our daily lives that we can't recognize them.

Elevators

We go to work every day, and elevators are a necessary device in the tall building. While PLC also plays a necessary part in the elevator. There is a defined program running in a PLC that detects the different floors requesting the elevator and directs the elevators in their required direction. Without it, the elevators may not find the destination correctly. The controllers are usually not located in the elevator itself but at a specific location on the roof of the building or in a nearby control room. Most elevators are programmed and controlled by PLCs to take the most optimized route through any pending button calls and make their directional decisions based on that.

Automatic doors

Have you ever been hit by an automatic door? Thanks to PLC control, it greatly prevented this incident. With a built-in sensor on both sides of the automated doors, for example, they can detect whether the beam of light is broken and recognize there may be something between them.

Roller coasters

Many people enjoy pushing themselves to new heights and experiencing the sensation of near-death. What is that exciting thing, Sure, the most attractive facilities in the amusement park-roller coaster.

Typically, the PLC control in roller coasters is used to pull it up before the major drop. It is also utilized for safety measures to ensure that autos do not reverse direction. Imagine traveling backwards on the massive dip; it wouldn't be as exciting as the gravitational force dragging down.

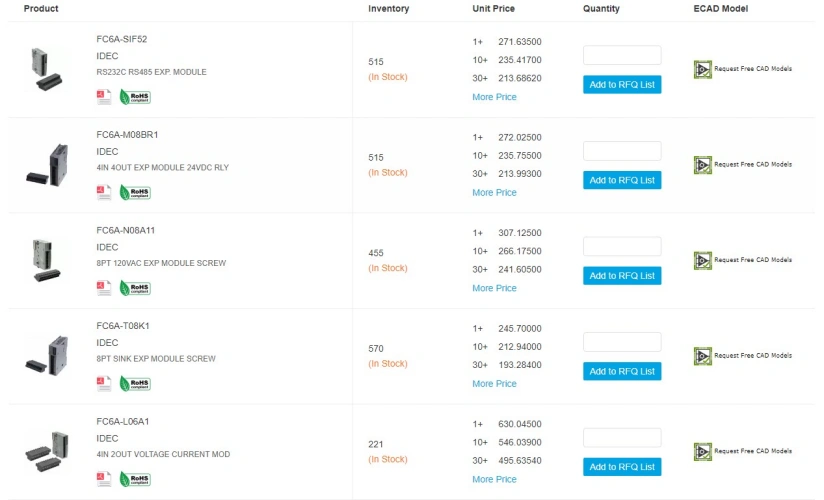

Where to buy quality PLC module

Established in 2004, Chipsmall Limited is headquartered in Futian, Shenzhen, with representative and branch offices in Hong Kong, Singapore, Mexico, France, Canada, and Zhongshan.

As the first self-operated electronic component e-commerce platform in China, Chipsmall can provide adequate stock and price information, as well as chip labels, appearance, and wafer information, greatly improving the efficiency of distinguishing between genuine and counterfeit products. Quality is the lifeblood of our product. We follow the quality inspection standard of "IDEA-STD-1010-B" and operate by international standard systems such as AS9120B, ESD, ISO9001, and ISO14001.

Order PLC module Now

PLC exists in our everyday life. PLC module can add more functions to many devices. These modules are required for communicating and data exchanging through the input or output signal. If you want to buy programmable logic controller module or related parts, please feel free to contact Chipsmall.

Disclaimer: The views and opinions expressed by individual authors or forum participants on this website do not represent the views and opinions of Chipsmall, nor do they represent Chipsmall's official policy.

share this blog to: