OUTLINE:

Shockingly Useful: The Line Tester's Guide to Electrical Safety

166

166Are you feeling a little wired about electrical safety? Don't worry, we've got you covered with the line tester's guide to staying shock-free. Sure, it's not the most glamorous tool in the electrician's toolkit, but the humble line tester can save your life (and your gadgets) by identifying live wires and faulty circuits. Get ready to plug into the electrifying world of the line tester!

A line tester is an electrical tool used to test the presence of current and identify live wires in electrical installations. When its metal tip touches a live circuit, a small light inside glows.

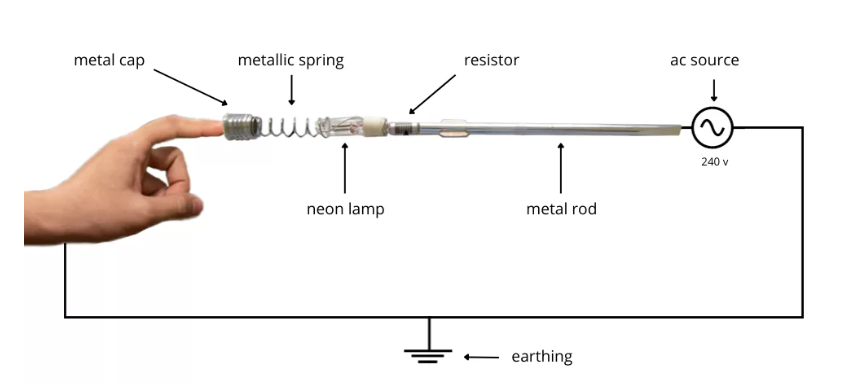

Major Components

- Resistor

- Neon bulb

- Metallic spring

- Metallic cap screw and clip

- Body and insulation

Some line testers also have additional features, such as built-in tone generators that can be used to locate cables in walls or ceilings.

Usage

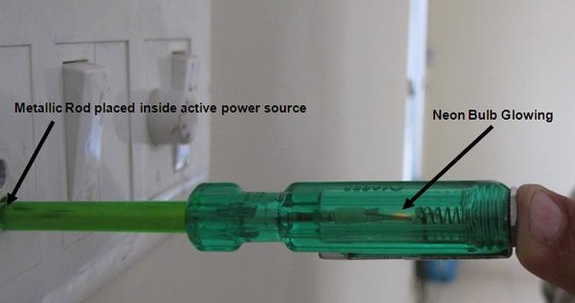

When the mouth of the metallic rod is touched to a live wire/phase, and our finger touches the metallic cap screw or clip, it completes the circuit and causes a small current to pass through the metallic rod. The resistor reduces the high current to a safe value, and the current passes through the neon bulb, causing it to glow. The element or metallic spring is used to connect the neon bulb to the metallic cap screw.

If the neon bulb glows, it indicates that the wire that was touched is carrying a current and is a live wire/phase, but if it doesn't glow, it means that the wire is a neutral wire/conductor.

Safety Considerations

When using a line tester, it is important to follow proper safety procedures to avoid electrical shock or injury. Always make sure the circuit is turned off and de-energized before testing, and use insulated probes to avoid coming into contact with live wires.

Types of Line Testers

There are different types of line testers available, including digital and analog testers. Digital testers have an LCD display that shows readings, while analog testers use a needle or LED lights to indicate readings. Some line testers are designed for specific applications, such as network cable testers or automotive circuit testers.

Application

Electrical wiring: A line tester can be used to check for electrical continuity, voltage, and current in wiring systems. It can help identify faults, shorts, or open circuits in electrical circuits.

Network cables: A line tester can be used to check for proper connections, continuity, and signal strength in network cables. It can help identify faulty cables, connectors, or network devices.

Telephone lines: A line tester can be used to check for proper connections, continuity, and signal strength in telephone lines. It can help identify faulty lines or equipment, such as damaged cables or broken jacks.

Automotive circuits: A line tester can be used to check for continuity and voltage in automotive circuits, such as those in a car's electrical system. It can help identify issues like blown fuses, faulty relays, or damaged wiring.

HVAC systems: A line tester can be used to check for proper voltage and continuity in HVAC systems, such as those in air conditioning or heating units. It can help identify faulty components like capacitors, relays, or motors.

Line testers can help save time and money by quickly identifying faults or issues in electrical, network, and other systems. They can also help prevent damage to equipment and reduce the risk of electrical shock or injury. By regularly testing and maintaining systems, line testers can help ensure that they are functioning properly and prevent more serious problems from occurring.

Disclaimer: The views and opinions expressed by individual authors or forum participants on this website do not represent the views and opinions of Chipsmall, nor do they represent Chipsmall's official policy.

share this blog to: