OUTLINE:

Thermal Pad: Why and How to Use

146

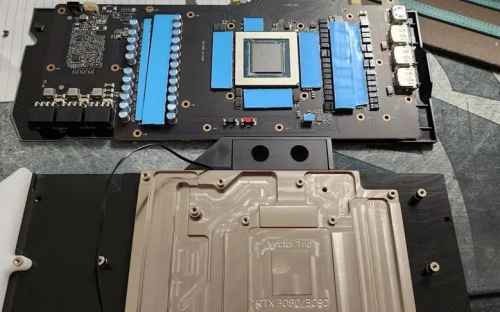

146Thermal pad is a composite material with a certain thermal conductivity and flexibility, which is mainly used for filling the gap between the semiconductor device and the radiator to improve the transferring efficiency against excessive heat generated by the semiconductor device at work. It is also designed for heat dissipation of electronic devices, which is usually placed between the heat component and the heat dissipation structure of the device to help conduct normal temperature for practical operation, thereby improving efficiency and protecting the electronic device.

The main function of the thermal pad is to conduct heat away from the device through its internal microporous structure, and effectively transfer heat from the top copper layer of the printed circuit board (PCB) to the inner or bottom copper layer or the external environment.

Image Source: aok-technologies.com

Features and Applications of Thermal Pad

Features

Thermal Pad is a composite material with a certain thermal conductivity, and some main characteristics which make it popular and beneficial in technological application are listed as follows.

High thermal conductivity

Thermal pad can effectively transfer heat from the heat source to the radiator, thereby improving the heat dissipation efficiency of electronic devices.

Low thermal resistance

Low thermal resistance means better heat transferring performance, which is essential to maintain the stable operation of electronic components over the operating temperature range.

Easy to attach and tear

The design structure of the thermal pad makes it very convenient for both attaching and removing, which helps to simplify the assembly process and reduce the time cost.

High cost efficiency

The low cost of thermal pads compared to other heat dissipation solutions has made it widely used in electronic products.

High mechanical strength

Although the thermal pads are usually soft, it still maintains a certain mechanical strength to ensure that it will not be easily damaged during assembly and use.

In addition, certain thermal pad products have other characteristics, such as self-adhesive properties and reusability, which further improve the ease and cost effectiveness of operation.

Applications

Thermal pad, as an important heat conduction and heat dissipation material, is widely used in electronic devices, automotive electronics, industrial equipment and other fields. It can fill the tiny gap between the electronic device and the radiator, improve the heat dissipation efficiency, and protect the electronic device from overheating damage.

In PCB wiring, thermal pad is also often used as a special form of pad, such as a cross bridge or a line bridge. This design is mainly to prevent the impact of the severe expansion caused by the high temperature molten tin into the hole, avoiding the possible stratification. By leaving four notches at the bottom between the pads, the effect of thermal shock can be reduced, so it is also known as the heat insulation disc.

Besides, the density of thermal pads directly affects the heat dissipation effect. The higher the density, the higher the thermal conductivity per unit area, the better the heat dissipation performance. Therefore, when selecting a thermal pad, it is necessary to determine the appropriate density according to the heat dissipation requirements of the electronic device. Generally speaking, for high-power equipment, a high-density thermal pad should be selected to improve the heat transfer efficiency; For low-power devices, it is suggested to use a low-density one.

Material of Thermal Pads

For thermal pads, silicone and graphite are two of the most used form factors. They are not, however, the only options available. These substitute options consist of: Fiberglass, Acrylic, Polyester or Aluminum.

Silicone pads

A very useful and adaptable material for thermal pads is silicone. A remarkable variety of design needs may be satisfied using silicone, which can be produced in a broad range of thicknesses and compression levels. Silicone heat pads also have advantageous electrical isolation qualities.

Graphite pads

For designs that need for a thin, highly conductive thermal interface material, graphite is a great option. Its smaller construction, which is intended for high-performance applications, necessitates comparatively flat and parallel surfaces in order to achieve optimum thermal performance and wet-out.

Top 3 Best Thermal Pad Suppliers In The Market

After learning some basic knowledge about thermal pads, in this section, it is time for further recommendation of the top 3 manufacturers for helping you choose the best product you need. The following data is collected based on the market research about the quantity, brand influence and consumer feedback of thermal pads. So let’s get started!

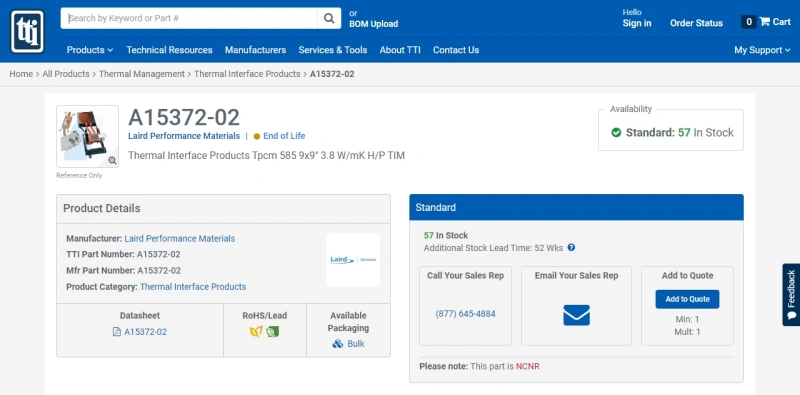

TTI

TTI is the world's leading professional distributor of passive components, discrete devices, connectors and electromechanical components. Also, the company has a large inventory, maintaining over 500,000 pieces of inventory over the long term, more than 80% of which can be delivered immediately in an emergency. This ensures that products purchased on the TTI shopping website can be shipped quickly to meet customers' urgent needs. And the shopping site has a user-friendly design that makes it easy for customers to browse and search for the products they need, providing detailed shopping guides and customer service information.

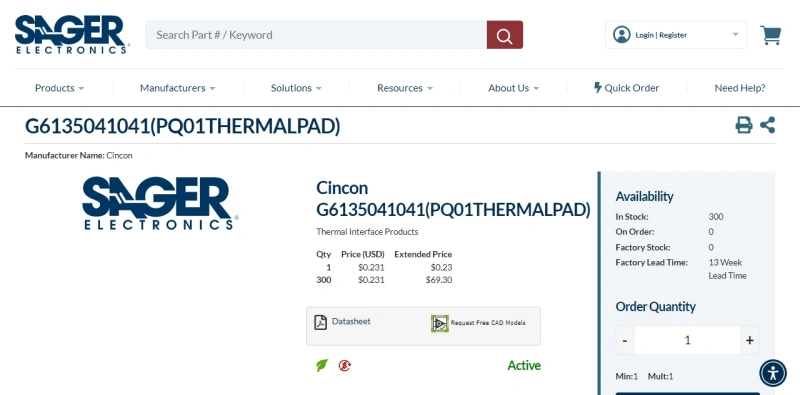

Sager Electronics

Sager Electronics is a company with strong potential in the field of electronic component business, distributing products from more than 90 leading manufacturers worldwide. And the company serves its customers through strategic service centers throughout North America, each of which owns a sales team, including sales management, experienced in-house sales and product teams.

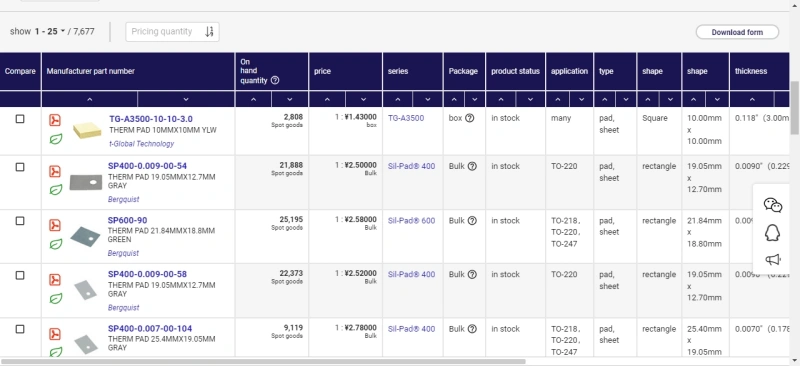

DigiKey

DigiKey is known for its off-the-shelf direct sales business model and extensive library of electronic components, with more than 750 licensed vendors and more than 15 million products covering LED lighting, RF and wireless, semiconductors, and more. The company has a large inventory to ensure that customers get the products they need quickly. Also, DigiKey has an extensive sales network and customer support centers. With its excellent product quality, professional service and innovative business model, it has won a wide reputation and customer trust in the electronic components distribution industry. As one of the global leaders in the distribution of electronic components, DigiKey will continue to be committed to providing customers around the world with high-quality electronic components and professional services to promote the development of global innovation.

Make A Choice: Thermal Pad VS Thermal Paste

Thermal pads and thermal pastes are thermal interface materials frequently used in electronic devices, especially between cpus and other heating components and heat sinks, to improve the efficiency of heat transfer. Their main function is to form a layer of thermal conductive medium between the heat source and the radiator to reduce the thermal resistance caused by the air gap, thereby improving the heat dissipation efficiency. And the table illustrated below are some basic differences between the two.

|

Contrast Dimension |

Thermal Pad |

Thermal Paste |

|

Price |

Lower |

Higher |

|

Advantage |

Good heat conductivity, suitable for heat dissipation in a large area. |

Suitable for small areas or hard-to-reach heat dissipation requirements. |

|

Disadvantage |

Not suitable for small area or complex shape heat dissipation. |

The cost is high and may affect the maintainability of the equipment. |

|

Usage scenario |

Large electronic equipment, servers, etc. |

Small electronic equipment, precision instruments, etc. |

|

Thermal efficiency |

High thermal efficiency, suitable for continuous heat dissipation. |

Efficient but may vary depending on the application environment. |

|

Environmental protection property |

Depending on the material, some may contain harmful substances. |

Generally more environmentally friendly and free of harmful substances such as silicates |

|

Service life |

Good long-term stability and durability. |

It is highly affected by environmental factors and may need to be replaced frequently. |

Final Verdict

As an effective means of heat dissipation for electronic equipment, the design and application of thermal pads are progressing with the development of technology. When selecting a thermal conductivity pad, factors such as thermal conductivity, hardness, and temperature resistance range should be comprehensively considered according to the specific application scenarios and requirements to ensure the normal operation and performance of electronic devices.

Disclaimer: The views and opinions expressed by individual authors or forum participants on this website do not represent the views and opinions of Chipsmall, nor do they represent Chipsmall's official policy.

share this blog to: