OUTLINE:

Where to Buy Quality Toroidal Transformer

149

149Toroidal transformers have the advantages of small size, low noise, low heat generation, and high conversion efficiency, and have been increasingly used in industrial automation equipment, instruments, and household appliances. Toroidal transformers, especially in the application of stepper motor power supplies, have shown excellent performance, far exceeding the performance of U-type and E-type transformers.

What is a toroidal transformer

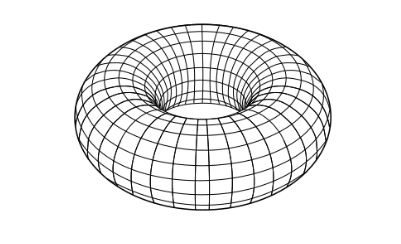

Toroidal transformers are a common type of electronic transformer that resembles a doughnut, used in household appliances and other high-tech electronic devices. Its primary applications are as a power transformer and an isolation transformer. Toroid core materials include ferrite rings, silicon steels, and powdered iron.

A typical toroidal transformer is formed by a ring-shaped magnetic core and two layers of coils called the primary winding and the secondary winding wiring surround the core. Besides the core insulation, between the primary and the secondary winding there lies an insulation substance that is often made from PET film (see the figure). It's similar to a solenoid, but it's curved.

Compared to conventional shell and core type transformers, toroidal transformers offer more design flexibility, efficiency, and compactness, making them the perfect choice for low-KVA (up to 15 KVA) rated devices and equipment used in industrial, medical, renewable energy, and audio applications.

Working principles of toroidal transformers

The working principle of the toroidal transformer is the same as that of the ordinary transformer, which is based on the principle of electromagnetic induction. Secondly, the core of the toroidal transformer is made of high-quality cold-rolled silicon steel sheets (sheet thickness is generally less than 0.35mm), which is seamlessly rolled, which makes its core performance better than the traditional laminated core. The coil of the toroidal transformer is evenly wound on the core, and the direction of the magnetic lines of force generated by the coil is almost completely coincident with the magnetic circuit of the core. Compared with the laminated type, the excitation energy and core loss will be reduced by 25%.

Types of toroidal transformer

Toroidal transformers can be classified into three types: standard type, economic type, and isolated type:

1. Standard type

The standard power transformer series has a capacity of 8-1500VA, a low voltage adjustment rate, and a temperature rise of under 40℃ during full load operation. It supports short-term overload operation and is ideal for high-demand applications. The primary and secondary windings are insulated with Class B polyester film (130°C). The AC 4000V, 1 minute withstand voltage test requires at least three layers of insulating tape.

2. Economic Type

The economical power transformer product line, with a capacity of 50-1500VA, aims to decrease costs while ensuring reliable performance. It is capable of continuous operation without overload. The operational temperature rise is 60℃, and the insulation material grade is A (105℃). When the load is full, the output voltage inaccuracy is less than 3%.

3. Isolated type

The isolation transformer product series has a capacity range of 50-1000VA and is divided into two series: industrial and medical equipment. The isolation transformer focuses on insulating performance. Between the primary and secondary, wrap at least four layers of Class B insulating polyester film with a breakdown voltage greater than 4000V, and all primary leads must be doubly insulated. The transformer's maximum temperature rise is less than 45 degrees Celsius. In addition to achieving the above standards, medical isolation transformers must also meet the UL544 standard, which states that the main and secondary windings must be thermally protected, and the distance between the winding and the grounded copper shield must be at least 13mm.

Toroidal Transformer Application Areas

Medical Industry: The medical business requires high accuracy and outstanding efficiency. Toroidal transformers can effectively meet both of these requirements. They ensure minimum current leakage and consistent performance under specified conditions. Because of their small design, these transformers are easily integrated into medical devices when space and weight are limited.

Electrical Circuits: Transformers are widely employed in electrical circuits such as inverters, computers, televisions, amplifiers, and audiovisual applications.

Why do power amplifiers use toroidal transformers?

Nowadays, many electronics enthusiasts choose toroidal transformers when choosing audio power amplifier transformers. The use of toroidal transformers in audio power amplifiers is determined by the characteristics of audio power amplifiers.

The power consumption of audio power amplifiers is basically different from that of other equipment. The power consumption of audio power amplifiers not only changes quickly, but also changes greatly. This requires that the transformer must have strong instantaneous overload capacity and fast response speed, otherwise it will easily form noise, the sound is not full, and the sound quality is poor.

The toroidal transformer has a large capacity in the same volume, and the direct coupling type has almost zero delay response, which can meet the characteristics of audio power supply.

Advantages of toroidal transformers in audio amplifiers:

1. High electrical efficiency, no air gap in the core, high stacking coefficient.

2. Small size and light weight. The weight of toroidal transformers can be reduced by half compared to laminated transformers.

3. Small magnetic interference. The core of the toroidal transformer has no air gap. The winding is evenly wound on the annular core. This structure leads to small magnetic leakage and small electromagnetic radiation.

4. Small vibration noise. The core has no air gap, which can reduce the noise of the core induced vibration. The winding evenly and tightly wraps the annular core, effectively reducing the "buzzing" sound caused by magnetostriction.

5. Low operating temperature. Due to the iron loss, the iron loss is very small, the core temperature rise is low, and the winding has good heat dissipation on the core with lower temperature, so the transformer temperature rise is low.

6. Easy to install. The toroidal transformer has only one mounting screw in the center, which is particularly easy to install and disassemble quickly in electronic equipment.

TOP 5 Transformer Manufacturer

1. Siemens

Siemens is a German multinational corporation and one of the major industrial manufacturing firms in Europe. Industries covered by Siemens include aerospace, automotive, chemical, mining, oil and gas, food and beverage, cranes, cement, and pharmaceutical. Among the major transformer producers, the firm provides devices for all outputs and voltages. The company builds its products with environmental sustainability and efficiency in mind, as well as compliance with EU standards and guidelines. The company's products include power transformers, reactors, phase shifting transformers, HVDC transformers, distribution transformers, and traction transformers.

2. Schneider

Schneider Electric, founded in 1836 by Adolphe and Joseph-Eugène Schneider, is a global leader in energy management and automation. The company is headquartered in Rueil-Malmaison, France, and is renowned for its innovative solutions in energy efficiency, sustainability, and smart infrastructure across various industries.

3. Toshiba

Tshiba Energy Systems & Solutions Corporation is a subsidiary of the Toshiba Group, a Japanese multinational corporation usually known as "Toshiba" (TOSHIBA) with over 135 years of industry experience.

Toshiba Energy Systems & Solutions Corporation offers energy-related solutions such as heavy ion therapy, energy transmission and distribution, renewable energy generation systems, and energy aggregation services.

4. ABB

ABB is a well-known power transformer manufacturer and a multinational firm that provides robotics, power, and automation services. It sells gadgets and instruments used in power grids, electrification, transportation, and utilities. It also creates measurement and sensing devices for circuit breakers and medium voltage switch gears to monitor energy consumption. ABB is a significant transformer manufacturer that produces both liquid-filled and dry-type transformers, as well as offering full life-cycle support, including replacement parts and components.

5. GE

GE is a multinational business that operates in numerous industries, including energy connections, digital, oil and gas, renewable energy, transportation, electricity, and healthcare. It is a leading transformer producer that also operates in the technology and infrastructure sectors. Additionally, it provides gas and steam power system solutions, which include transformers. GE, one of the most efficient transformer manufacturers, asserts that their transformers are very efficient since they fulfill the DOE 2016 efficiency requirement and include additional features. The company's transformers are classified as dry-type vented, dry-type non-ventilated, dry-type encapsulated and enclosed, control power core and coil, secondary substation, power and distribution.

Disclaimer: The views and opinions expressed by individual authors or forum participants on this website do not represent the views and opinions of Chipsmall, nor do they represent Chipsmall's official policy.