OUTLINE:

Unveiling the Power of Chip X-Ray Detection in Electronics

300

300In the realm of electronics manufacturing, ensuring the quality and reliability of integrated circuits (ICs) is paramount. One powerful tool that has revolutionized the inspection process is chip X-ray detection. By harnessing the penetrating power of X-rays, this technology enables detailed imaging of ICs, exposing defects, and facilitating quality control. In this article, we will delve into the world of chip X-ray detection, exploring its significance, benefits, and applications.

The Principle of Chip X-Ray Detection:

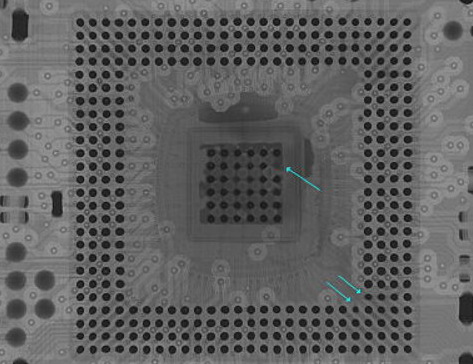

Chip X-ray detection operates on the principle of X-ray imaging, where X-rays are emitted and pass through the ICs. As they interact with different materials and structures within the chip, they are either absorbed or scattered. A detector captures the transmitted or scattered X-rays, generating an image that reveals the internal features and potential defects of the IC.

Detecting Internal Defects:

One of the primary applications of chip X-ray detection is the identification of internal defects in ICs. These defects can include wire bond issues, solder joint irregularities, voids, cracks, delamination, and package integrity problems. By visualizing the internal structure, X-ray inspection helps identify these flaws at an early stage, ensuring the ICs meet the required quality standards.

Non-Destructive Testing:

One of the key advantages of chip X-ray detection is its non-destructive nature. Unlike other testing methods that require physical disassembly or alteration of the IC, X-ray inspection allows for thorough analysis without compromising the integrity of the component. This non-destructive feature is particularly valuable for high-value ICs or those intended for critical applications.

Quality Control and Process Optimization:

Chip X-ray detection plays a vital role in quality control and process optimization. By examining the internal features of ICs, manufacturers can identify process-related issues, such as improper wire bonding, voids in solder joints, or inadequate encapsulation. These insights enable process refinement, leading to enhanced yield, reduced failure rates, and improved overall product quality.

Counterfeit Detection:

Counterfeit electronic components pose a significant risk to the industry, affecting product performance, reliability, and safety. Chip X-ray detection serves as a powerful tool in counterfeit detection efforts. By inspecting the internal structure of ICs, it helps identify counterfeit components that may have altered or substandard internal features, such as incorrect die placement, different wire bonding patterns, or inconsistent packaging.

Failure Analysis:

When ICs fail in the field or during reliability testing, thorough analysis is crucial to identify the root cause. Chip X-ray detection aids in failure analysis by providing detailed images of the failed components. This allows engineers to examine potential failure mechanisms, such as bond wire damage, solder joint cracks, or delamination, aiding in the development of corrective actions and preventive measures.

Advanced Packaging Technologies:

With the rapid advancement of packaging technologies such as flip-chip, stacked die, and wafer-level packaging, chip X-ray detection has become indispensable. These advanced packaging techniques often involve complex internal structures that cannot be easily inspected using traditional optical methods. X-ray imaging provides a clear view of the intricate interconnections and enables thorough analysis of these advanced packages.

Chip X-ray detection has emerged as a powerful technique in the realm of electronics manufacturing. Its ability to visualize the internal structure of ICs enables the detection of defects, aids in quality control, assists in counterfeit detection, supports failure analysis, and facilitates the inspection of advanced packaging technologies. As the electronics industry continues to evolve, chip X-ray detection will remain a vital tool for ensuring the reliability and quality of integrated circuits.

Disclaimer: The views and opinions expressed by individual authors or forum participants on this website do not represent the views and opinions of Chipsmall, nor do they represent Chipsmall's official policy.

share this blog to: