OUTLINE:

A comprehensive guide: what is a stepper motor

232

232Stepper motor is a kind of component that can convert electrical pulse signals into precise rotating motion. Its working principle is based on the principle of electromagnetism, by controlling the current on and off and direction, so that the rotor of the motor rotates according to the predetermined step Angle. When the stepper driver receives a pulse signal, it drives the stepper motor to rotate at a set fixed Angle (called the "step Angle"). The stepper motor is characterized by accurate position control, because its rotation Angle is proportional to the number of input pulses, and the speed is proportional to the pulse frequency. By controlling the number of pulses, the angular displacement of the stepper motor can be precisely controlled, so as to achieve accurate positioning. At the same time, by controlling the frequency of the pulse, the speed and acceleration of the motor can be controlled, so as to achieve the purpose of controlling the speed.

Working principle of stepper motor

Stepper motor is mainly composed of stator and rotor. The stator has multiple windings, usually two, three or more phases. The rotor is usually composed of multiple magnetic poles, which can be permanent magnets or electromagnets activated by an electric current. When the current passes through the stator's windings, it creates magnetic fields inside the motor, which interact with the magnetic poles on the rotor to produce torque, which drives the rotor to spin.

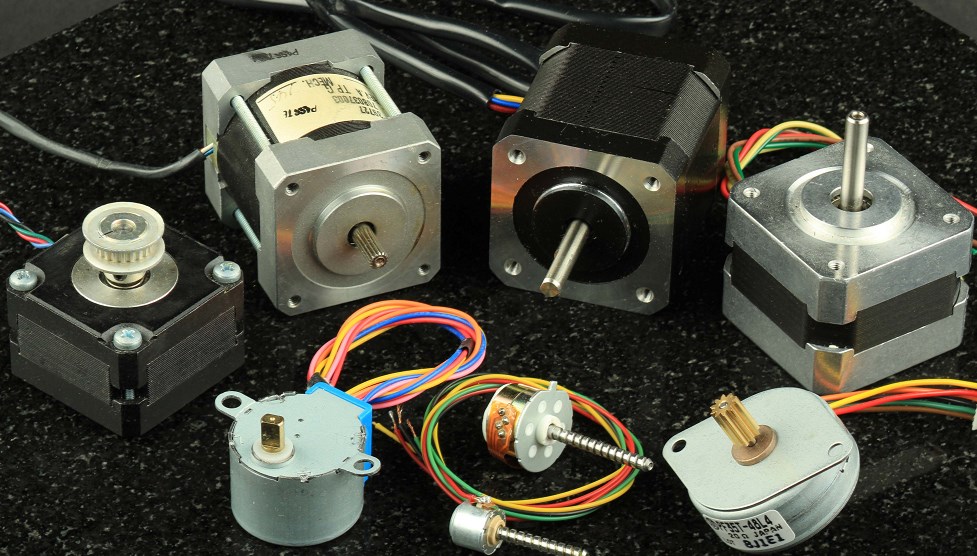

Structure and type of stepper motor

The structure of the stepper motor usually includes a stator and a rotor. The stator is composed of an iron core and a coil wound around it. When the coil is energized, a magnetic field is generated, which becomes an electromagnet. The rotor is a permanent magnet, and its magnetic field is affected by the stator's magnetic field, which is attracted or repelled, causing the rotor to rotate. In the stepper motor, there are usually two or more groups of coils, corresponding to different magnetic poles. By controlling the power sequence and current size of these coils, you can control the rotation direction and Angle of the rotor.

Stepper motor is a kind of motor that converts electrical pulse signal into mechanical angular displacement, which is widely used in the field of precision positioning and automatic control. The structure types of stepper motor mainly include the following:

|

Different Types of Stepper Motor |

|

|

Variable Reluctance, VR |

The rotor of this motor is made of soft magnetic material and has no winding. The stator has windings that generate a magnetic field by controlling the opening and closing of an electric current, which drives the rotor. The reactive stepper motor has the advantages of simple structure and low cost, but poor dynamic performance, low efficiency and large heat output. |

|

Permanent Magnet, PM |

The rotor of the permanent magnet stepper motor uses a permanent magnet material, and the number of poles of the rotor is the same as that of the stator. This kind of motor is characterized by good dynamic performance, large output torque, but the accuracy is relatively low and the step Angle is large. |

|

Hybrid Stepping, HS |

The hybrid stepper motor combines the advantages of reaction type and permanent magnet type. The stator has polyphase winding, the rotor adopts permanent magnet material, and the rotor and stator are equipped with small teeth to improve the precision of step moment. Hybrid stepper motor is characterized by large output torque, good dynamic performance and small step Angle, but the structure is relatively complex and the cost is high. |

|

Single-phase stepper motor |

Single-phase stepper motor is a kind of stepper motor, which is usually composed of a circular coil wound on a coil skeleton, by passing a positive and negative alternating current to the coil, each time the current is switched one step in a fixed direction. Because the magnetic permeability (the reciprocal of the magnetic resistance, indicating the ease of flux flow) passed by the rotor magnetic circuit becomes larger than its rotation direction, the single-phase stepper motor can only move in one direction. In order to determine the direction of rotation, a variety of measures are taken to make the stator magnetic pole wider than the rotor, the working air gap between the stator and the rotor is not uniform, and the direction of rotation is the direction of small reluctance. |

|

Planar stepper motor |

Planar stepper motor is a special type of stepper motor, which is characterized by the structural layout of its stator and rotor on a plane. Such motors typically have a small size and lightweight design for precision positioning applications that require a compact layout. The design of planar stepper motor can optimize the magnetic circuit and improve the efficiency and response speed of stepper motor. |

Characteristics and performance of stepper motor

Stepper motor is a kind of motor that converts electrical pulse signals into angular displacement or linear displacement. It precisely controls the rotation Angle of the rotor by controlling the sequence of electrification and the number of pulses in the stator windings. Each time a pulse signal is received, the rotor rotates at a fixed step Angle, thus achieving precise position control. Stepper motors usually do not require position feedback systems because their controls are open-loop, but modern stepper motor systems may include position feedback to improve control accuracy.

Firstly, let’s talk about the various characteristics of stepper motor. To make it more simple, we can see the table below.

|

Characteristics of stepper motor |

|

|

High-precision positioning |

The stepper motor can achieve precise position control by controlling the pulse signal, usually the step Angle can reach 0.9 degrees or less. |

|

Simple control mode |

The control of the stepper motor is relatively simple, only the pulse signal can be provided to control its movement, the interface of the controller and the motor is simple, easy to integrate and apply. |

|

High torque low speed drive |

The stepper motor has a high torque at low speed, which is suitable for occasions requiring large torque low speed drive. |

|

Brushless design |

The stepper motor has no wearing parts such as brushes and capacitors, so it has a long life and high reliability. |

|

Reversibility |

The stepper motor can change the direction of rotation of the rotor by reversing the direction of current. |

|

Low noise operation |

Because the stepper motor has no brush, its running noise is low, and it is suitable for occasions with high noise requirements. |

|

Controllable speed and acceleration |

Speed and acceleration of the stepper motor can be controlled by adjusting the pulse frequency and pulse width. |

Secondly, let's look at the excellent performances of the stepper motor.

1. Holding torque. When the stepper motor is energized but not rotated, the stator locks the rotor torque.

2. Pull-in torque: The minimum torque that can overcome the load and maintain stable operation when the stepper motor is started.

3. Out-of-step torque: The torque that the stepper motor can continue to rotate beyond its stable operating range.

4. Step Angle: The Angle of rotation of each pulse signal received by the stepper motor, the smaller the step Angle, the higher the resolution of the motor.

5. No-load starting frequency: the pulse frequency that the stepper motor can start normally under no-load condition.

6. Maximum no-load operating frequency: the highest speed frequency that the stepper motor can achieve without load.

Control methods of stepper motor

In order to operate properly and efficiently, stepper motor will take up different types of control methods, selecting the appropriate mode can optimize the performance of the stepper motor and meet the needs of specific applications. In practical applications, a combination of control strategies may be used to achieve the best control effect.

|

Control methods of stepper motor |

|

|

Full step control |

This is the most basic control mode, each pulse signal makes the motor rotate a complete step Angle. This approach is suitable for applications that require high precision positioning. |

|

Half step control |

Improved on the basis of full step control, each pulse signal makes the motor rotate half step Angle, the speed is faster but the accuracy is low. |

|

PID control |

A feedback control method that adjusts the motor torque by measuring the error between the actual position and the target position, suitable for complex and highly dynamic applications. |

|

Vector control |

The use of motor mathematical model to optimize performance, suitable for high performance and reliability requirements of the application. |

|

Open loop control |

Simple control, easy to achieve, low price, but not high precision, sometimes there will be loss of step, oscillation and other phenomena. |

|

Closed-loop control |

Through the encoder feedback the actual position of the rotor, and compared with the input signal, through the controller to adjust the output, can improve the system dynamic response performance, suitable for high precision occasions. |

|

Pulse direction control |

By providing direction pulse and stepping pulse signal to the motor, the precise stepping control of the motor can be achieved, usually by using a stepper driver or controller. |

|

PWM control |

By changing the duty cycle of the PWM signal in the motor driver, the performance parameters such as the speed and torque of the motor can be controlled. |

Practical operation of stepper motor

The wide range of applications of stepper motors demonstrates their importance in modern industry and our daily life, especially where precise control and high dynamic response are required.

For example, a stepper motor is used to control the precise movement of the tool in CNC machine tools to achieve high-precision machining operations.

Besides, stepper motors are also widely applied in automated production lines. On automated assembly and packaging lines, stepper motors control the movement of workbenches, conveyor belts and robotic arms to improve production efficiency and quality.

Moreover, in household appliances, stepper motors are used in electric curtains, electric lifting equipment, etc., to provide smooth and precise control. In devices such as printers, scanners and projectors, stepper motors are used for functions such as accurate paper feed and image adjustment.

In addition to these, the stepper motor is also widely used in other fields, it is like an interesting but mysterious friend of ours, for it can be seen everywhere at any time.

Final Verdict

As an important executive element, stepper motor plays an indispensable role in modern industrial automation and digital control systems. Through in-depth understanding of the basic principles, structural characteristics and control methods of stepper motors, we can make better use of this technology to provide more accurate, efficient and reliable solutions to meet our needs.

Disclaimer: The views and opinions expressed by individual authors or forum participants on this website do not represent the views and opinions of Chipsmall, nor do they represent Chipsmall's official policy.

share this blog to: