OUTLINE:

Why We Need Fiducial Markers in PCB Design

389

389Fiducial markers may be small, but their impact on PCB manufacturing is significant. Proper fiducial marker placement is crucial for ensuring consistency and efficiency in the manufacturing process. Well-designed fiducial marks facilitate accurate machine alignment and component placement, preventing costly reprogramming and rework. Paying attention to fiducial placement upfront saves time, money, and potential headaches down the line.

What Is a Fiducial Marker?

A fiducial marker, also known as a fiducial or fiducial point, is a reference feature or mark used in manufacturing processes, including PCB assembly. Fiducial markers are typically small, distinctive patterns or shapes placed on a PCB to provide reference points for automated equipment and ensure accurate positioning and alignment. Without good fiducial markers, components may be placed incorrectly or machines may refuse to operate.

How Does Fiducial Maker Help?

The primary purpose of fiducial markers is to assist in the precise placement of components and alignment of PCBs during manufacturing processes. Here's how they help:

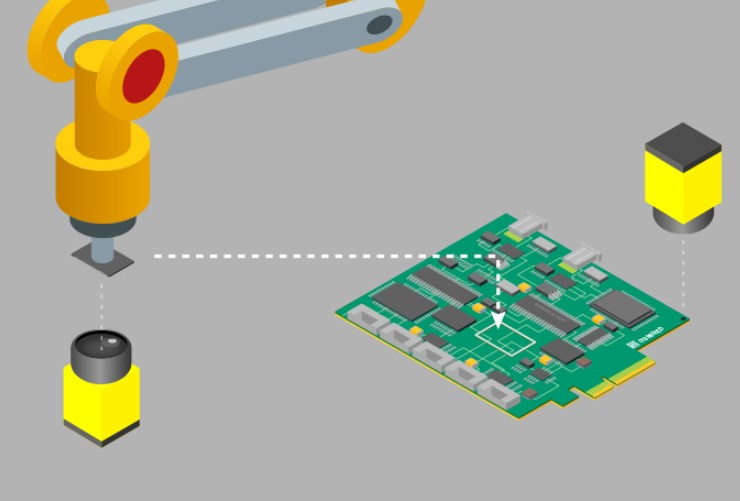

Alignment: Fiducial markers act as visual reference points for automated assembly equipment, such as pick-and-place machines or AOI systems. By analyzing the position and orientation of fiducials, the equipment can accurately determine the PCB's position, rotation, and scale, ensuring proper alignment of components.

Component Placement: Fiducial markers help in achieving accurate component placement on the PCB. Once the equipment locates the fiducials, it uses their known coordinates to calculate the position and orientation of other components relative to the fiducials. This information guides the pick-and-place machines to precisely position the components on the PCB.

Soldering and Inspection: Fiducials aid in the soldering process by ensuring proper alignment of components with their corresponding pad patterns. They help prevent misalignment, which can lead to soldering defects or poor electrical connections. Additionally, fiducials are used during automated optical inspection (AOI) to verify the correct placement of components and detect any potential assembly errors.

By using fiducial markers, manufacturers can improve the accuracy, repeatability, and quality of PCB assembly. These markers provide crucial reference points for automated equipment, enabling precise alignment, component placement, and inspection throughout the manufacturing process.

Types of Fiducial Markers

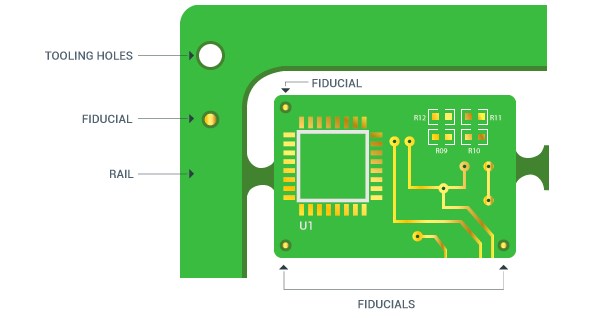

When it comes to fiducial markers in PCB designs, there are two common types: global fiducial marks and local fiducial marks.

Global fiducial markers (or panel fiducials) are placed near the corners of the PCB or on panelization rails. They help in aligning and holding multiple PCBs together during the assembly process.

Local fiducial markers are smaller and placed in areas with high-density components or complex routing. They enable precise component footprint location, reducing errors in fiducial placement.

To ensure accurate alignment, it's generally recommended to have at least two global fiducial marks placed on a three-point grid-based system—one in the lower left corner and another in the upper right corner of the board.

How to Add Fiducial Marker?

Location: Place fiducials on the top and/or bottom copper layers, ensuring they are not covered by solder mask. This allows the vision system to easily locate them.

- Shape: Round, square, or diamond shapes are suitable for fiducials. Most commonly, fiducials are round.

- Size: Opt for a fiducial diameter of around 0.050" (1.3 mm) for optimal visibility.

- Copper isolation: Avoid having copper nearby the fiducials, as this can interfere with the vision system's recognition of the fiducial marks.

- Spacing: To improve triangulation accuracy, position the fiducials as far apart from each other as possible.

Fiducial markers play a vital role in PCB manufacturing processes. They serve as reference points for precise alignment, accurate component placement, and reliable inspection. By strategically placing fiducial markers on PCBs, manufacturers can ensure consistency, efficiency, andthe overall quality of the manufacturing process. Proper fiducial marker placement saves time, reduces the risk of errors, and prevents costly rework. By paying attention to fiducial placement upfront, manufacturers can streamline their operations, optimize machine performance, and deliver high-quality PCBs.

Disclaimer: The views and opinions expressed by individual authors or forum participants on this website do not represent the views and opinions of Chipsmall, nor do they represent Chipsmall's official policy.

share this blog to: