OUTLINE:

How Does X Ray Inspection for Electronic Components Work

180

180X-ray inspection for electronic components is a non-destructive testing method that employs X-rays to scrutinize internal structures. This crucial technique ensures quality, reliability, and precise analysis without physically altering the components.

In this passage, let's see how X-ray inspection for electronic components works.

What is X-ray inspection for Electronic Components

X-ray inspection is a non-destructive testing technique that uses X-ray radiation to inspect the internal structure of objects. In the context of electronics and manufacturing, X-ray inspection is commonly employed to examine the internal features of components, assemblies, and materials without causing any damage.

An image of the x-rays that pass through the object is captured by a detector on the other side. The detector uses an x-ray sensor array to detect directly, or it first converts the x-rays into visible light, which is then captured by an optical camera. bringing the item under examination closer to the x-ray tube will allow for a higher magnification image, whereas bringing it closer to the detector will yield a lower magnification image.

This technique is especially valuable for identifying defects, ensuring quality control, and conducting failure analysis. X-ray inspection has emerged as a vital tool for defect detection, offering an in-depth analysis of PCB structures and uncovering hidden defects.

By leveraging the power of X-ray technology, manufacturers can enhance quality control, minimize production errors, and deliver electronic devices that meet the highest standards. Embracing PCB X-ray Inspection is a step toward achieving excellence in electronics manufacturing. X Ray Inspection plays a crucial and irreplaceable role in the field of electronic components.

How Does X-Ray Inspection for Electronic components work

X-ray inspection for electronic components works on the principle of X-ray attenuation, which is the reduction in intensity of X-ray beams as they pass through materials. Here's an overview of how X-ray inspection for electronic components typically works:

- X-ray Source: The process begins with an X-ray source, which emits X-rays. This source is positioned on one side of the object being inspected.

- Object Placement: The electronic component or assembly to be inspected is placed between the X-ray source and a detector. The object is positioned in the path of the X-rays.

- X-ray Transmission: When X-rays pass through the electronic component, they interact with the materials within the component. The degree of interaction depends on the density and composition of the materials.

- X-ray Attenuation: Dense materials, such as metal or solder, attenuate (absorb or scatter) more X-rays than less dense materials, such as plastic or air. As a result, the X-ray beam's intensity decreases as it passes through the object.

- Detector: On the other side of the object, there is a detector that captures the attenuated X-rays. The detector records the intensity and position of the transmitted X-rays.

- Image Formation: The information collected by the detector is processed to create an X-ray image of the internal structure of the electronic component. In the resulting image, areas with higher X-ray attenuation appear darker, while areas with lower attenuation appear lighter.

- Analysis and Inspection: The X-ray image is then analyzed by trained operators or automated software to identify various features, defects, or anomalies within the electronic component. This analysis can include examining solder joints, inspecting the placement of components, and detecting other internal issues.

- Quality Control and Inspection Criteria: The inspection process is guided by specific quality control criteria, including industry standards and specifications. This ensures that the electronic components meet the required quality and reliability standards.

- Documentation and Reporting: The inspection results are typically documented, and any identified issues are reported. This information is valuable for quality assurance, process improvement, and, if necessary, for addressing and correcting defects in the manufacturing process.

Benefits of X-Ray Inspections for Electronic Components

X-ray inspections play a crucial role in ensuring the quality and reliability of electronic components. Here are some benefits of X-ray inspections for electronic components:

1. Enhanced Defect Detection

X-ray inspection can unveil hidden defects that may not be visible to the naked eye. By utilizing X-ray radiation, manufacturers can ensure higher quality standards and minimize the risk of product failures.

2. Non-Destructive Testing

X-ray inspection enables manufacturers to thoroughly inspect the boards without compromising their functionality. It not only saves time and resources but also ensures that the PCBs maintain their structural integrity throughout the inspection process.

3. Increased Efficiency and Accuracy

It enhances the speed and precision of the inspection process, reducing the need for manual inspection and minimizing the potential for human error. By automating the inspection process, manufacturers can achieve higher throughput rates, allowing for a greater number of PCBs to be inspected within a shorter time frame.

4. Solder Joint Evaluation

X-ray inspections allow detailed evaluation of solder joints, especially in complex or miniaturized assemblies. By analyzing the solder joint quality, including the fillet formation and the presence of voids or defects, potential weaknesses can be identified, preventing solder-related failures and ensuring robust connections.

5. Identify Pin-hole Fills

Insufficient pin-hole fill for through-hole connectors is a frequent issue encountered in circuit boards. X-ray machines offer a solution to detect such errors and provide a quantitative assessment of the missing fill using coordinate measurements.

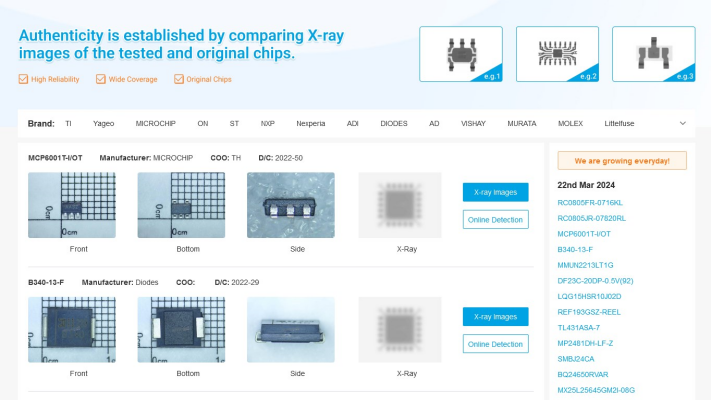

Free Chipsmall X-ray Inspection Service

Chipsmall is a trustworthy company that offers a free X-ray inspection service. You can view X-ray images free of charge. If you need any help with this, please don't hesitate to contact us. We are always ready to help.

X-ray chip inspection requires careful attention to safety issues. With the use of sophisticated safety technologies, radiation shielding measures, and thorough training, Chipsmall's X-ray chip inspection machines minimize any possible risks related to X-ray exposure while producing dependable and accurate findings.

Final Verdict

X-ray inspection is a valuable tool in quality control and assurance processes, especially in industries where precise and non-destructive analysis of internal structures is crucial. After reading this passage, hopefully, you'll have a comprehensive understanding of how X-ray inspection for electronic components works and its benefits.

Disclaimer: The views and opinions expressed by individual authors or forum participants on this website do not represent the views and opinions of Chipsmall, nor do they represent Chipsmall's official policy.

share this blog to: